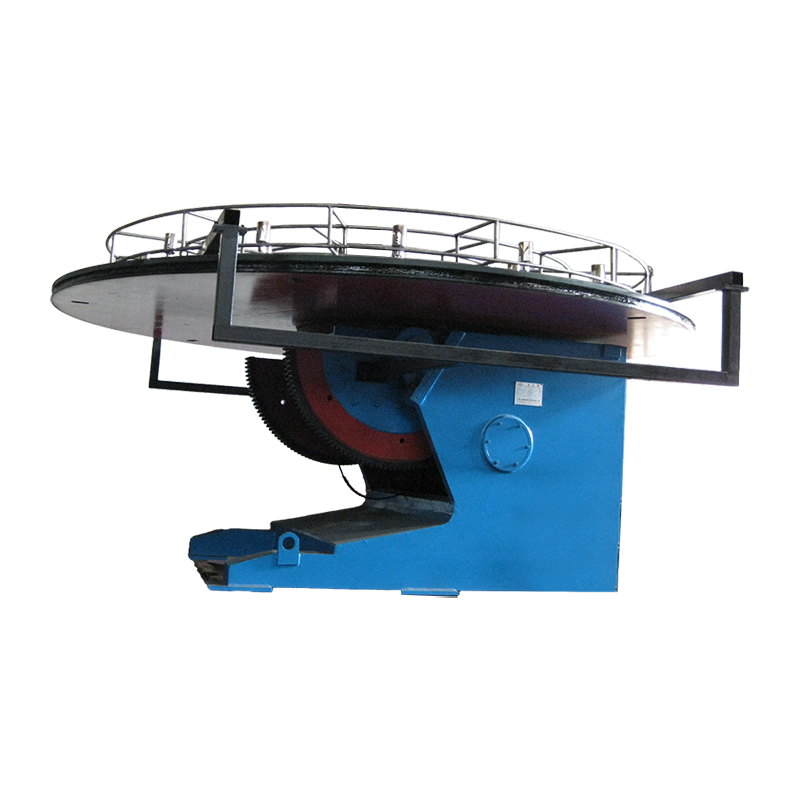

15T Welding Rotator with Additional Oven Support

15t welding rotator with additional oven support is specially designed for the manufacturing of large steel structures. It integrates welding displace...

See DetailsIn heavy-duty industries such as energy equipment manufacturing and large-scale pressure vessel fabrication, the primary challenge is not just the weld itself, but the safe and precise manipulation of the workpiece. A 15T Conventional Welding Positioner is a heavy-duty powerhouse designed to handle loads up to 15,000kg. By providing a stable platform for 360° continuous rotation and large-angle tilting, this equipment transforms a dangerous, multi-person handling task into a streamlined, single-operator process.

Traditional methods of moving 15-ton components often involve overhead cranes and heavy chains, which pose significant safety risks and can result in uneven weld beads due to unstable positioning. This equipment utilizes a high-strength steel frame that has been engineered to withstand extreme static and dynamic loads. By placing the weldment in the ideal "down-hand" position, manufacturers can achieve up to a 40% reduction in welding time while ensuring deep, consistent penetration throughout the joint.

The complexity of circumferential seam welding on massive shafts or cylinders requires more than just raw power; it requires surgical precision. The 15T Conventional Welding Positioner is equipped with advanced frequency conversion speed regulation technology. This allows the operator to adjust the rotation speed to match the exact deposition rate of the welding process, whether using Submerged Arc Welding (SAW) or high-current MIG/MAG systems.

Large-scale welding generates immense localized heat, which often leads to structural warping. The stable tilting motion of this positioner is specifically designed to minimize this risk. By maintaining a constant, vibration-free rate of movement, the system ensures uniform heat distribution across the workpiece. This stability is critical for pressure vessels, where even a minor deformation can lead to a failure in X-ray inspections or hydrostatic testing.

| Operational Metric | Manual Handling Method | 15T Conventional Positioner |

|---|---|---|

| Workpiece Setup Time | 90 - 120 Minutes | 15 - 20 Minutes |

| Weld Defect Rate | High (Due to Restarts) | Minimal (Continuous Seams) |

| Operator Safety Risk | Significant (Suspended Loads) | Negligible (Fixed Loading) |

Equipment used in the energy and oil & gas sectors must be "fail-safe." The 15T positioner is built with a reinforced slewing bearing and heavy-duty gearboxes to ensure smooth torque delivery at maximum capacity. The modular structure of the equipment is a key advantage for long-term maintenance. Components are easily accessible, allowing for routine lubrication and electrical checks without dismantling the entire unit.

To further enhance versatility, the table surface is equipped with standardized T-slots. These allow for the rapid mounting of heavy-duty welding chucks or specialized hydraulic clamps. In a multi-shift production environment, this standardized interface reduces "downtime between batches," as workers can switch fixtures in a fraction of the time required by custom-welded jigs.

As the industry moves toward Industry 4.0, the 15T Conventional Welding Positioner serves as the perfect foundation for automated welding cells. The system’s controller can be integrated with welding columns and booms or robotic arms. By synchronizing the positioner’s rotation with the movement of the welding torch, manufacturers can achieve fully automated 360-degree welding.

This level of integration not only improves production efficiency but also provides a repeatable quality standard that is impossible to achieve through manual labor alone.

Investing in a 15-ton positioner is a strategic financial decision. Beyond the immediate labor savings, the equipment significantly reduces the consumption of welding consumables. When a weld is performed in the optimal position, there is less spatter and lower risk of over-welding, which can save a facility thousands of dollars in wire and gas costs annually.

The "ideal choice" for heavy-duty welding is one that balances robustness with intelligence. With its combination of a stable steel frame, precision VFD speed control, and modular flexibility, the 15T Conventional Welding Positioner stands as an essential asset for any facility looking to lead in the manufacturing of heavy industrial components.