A Deep Dive into How Welding Column & Boom Systems are Reshaping Fabrication for Tanks, Pipes, and Pressure Vessels

In the global landscape of heavy manufacturing, the demand for large, robust, and impeccably constructed metal structures is ever-present. From the massive storage tanks that hold vital resources to the pressure vessels that operate under extreme conditions, the integrity of these products hinges on one critical process: welding. For decades, the fabrication of these components relied heavily on the skill and stamina of manual welders. However, as industry standards for quality, safety, and efficiency continue to rise, a significant shift is underway. A growing number of fabricators are now embracing automated solutions, with the Welding Manipulator/Welding Column & Boom /Welding Center/Automatic Welding system at the forefront of this transformation. This article explores the reasons behind this industry-wide movement, delving into the functionality, benefits, and customizable features of these advanced systems that are setting new benchmarks in metal fabrication.

The Inherent Hurdles of Manual Welding on a Grand Scale

Before understanding the solution, it's essential to appreciate the challenges of the traditional approach. Welding the longitudinal and circumferential seams of a large-diameter tank or a heavy-wall pressure vessel is a formidable task. Manual welding, while versatile, presents a series of significant hurdles in these applications:

Operator Fatigue and Inconsistency: A manual welder must maintain a steady hand, consistent travel speed, and precise torch angle for extended periods. Over the course of a multi-hour weld, physical fatigue inevitably sets in. This fatigue leads to variations in the weld bead, which can compromise the structural integrity and aesthetic quality of the final product. Inconsistencies such as varying bead width, undercutting, or lack of fusion are common issues that stem directly from human factors.

Difficult Working Conditions: Welding large structures often involves uncomfortable and potentially unsafe positions. Welders may be required to work at heights, in confined spaces, or in awkward postures to access the seam. This not only increases the risk of accidents but also makes it physically challenging to produce high-quality welds consistently.

Slow Production Rates: The deposition rate in manual welding is limited by what a single operator can safely and effectively manage. For thick materials requiring multiple weld passes, the process can be painstakingly slow, creating bottlenecks in the production schedule and extending project timelines.

Skilled Labor Shortage: The welding industry is facing a well-documented shortage of skilled professionals. Finding and retaining welders with the specific expertise required for high-pressure, code-quality work on large structures is an ongoing challenge for many fabrication shops. This scarcity drives up labor costs and can limit a company's production capacity.

High Material Waste: Inconsistencies in the welding process often lead to defects. Repairing these defects requires grinding out the bad weld and re-welding, which consumes additional filler material, shielding gas, and time. This rework adds significant cost to the manufacturing process.

Defining the Modern Fabrication Workhorse: The Welding Column & Boom

To address these challenges, the engineering community developed the Welding Manipulator/Welding Column & Boom /Welding Center/Automatic Welding system. At its core, this equipment is a sophisticated mechanical arm designed to precisely position and move a welding head along a predetermined path. The system typically consists of several key components:

- The Column: A sturdy, vertical structure that provides the main support for the system. It is designed to be rigid and stable, preventing vibration that could disrupt the welding process.

- The Boom: A horizontal arm that extends from the column. This boom can be raised, lowered, and extended or retracted, allowing the welding head to reach any point along the length of the workpiece. The movement of the boom is powered and controlled for smooth, precise operation.

- The Welder's Carriage/Saddle: A small trolley or saddle mounted on the boom that carries the welding torch, wire feeder, and sometimes other accessories. This carriage can traverse the length of the boom.

- The Control System: An interface that allows the operator to program and control the movement of the column and boom, as well as the welding parameters (voltage, current, wire feed speed, etc.). Modern systems feature user-friendly touch screens and intuitive controls.

By mechanizing the movement of the welding torch, this system removes the human element of physical strain and inconsistency. The result is a repeatable, reliable, and high-quality welding process that can operate continuously for long durations.

Core Functionalities That Drive Consistency and Quality

The effectiveness of a welding column and boom system lies in its ability to perform specific welding tasks with a high degree of precision. The source information highlights its wide application in welding inner and outer longitudinal and circumferential seams. Let's break down how this is achieved.

Welding Longitudinal Seams: A longitudinal seam is a straight, linear weld that runs the length of a cylindrical or flat structure. To weld this seam, the workpiece (e.g., a flat plate that will be formed into a cylinder) is positioned stationary. The boom of the manipulator is then aligned parallel to the seam. The welding carriage moves along the boom at a precisely controlled speed, while the welding head deposits a consistent, uniform bead. The operator can monitor the process from a safe, comfortable distance via a control pendant or station.

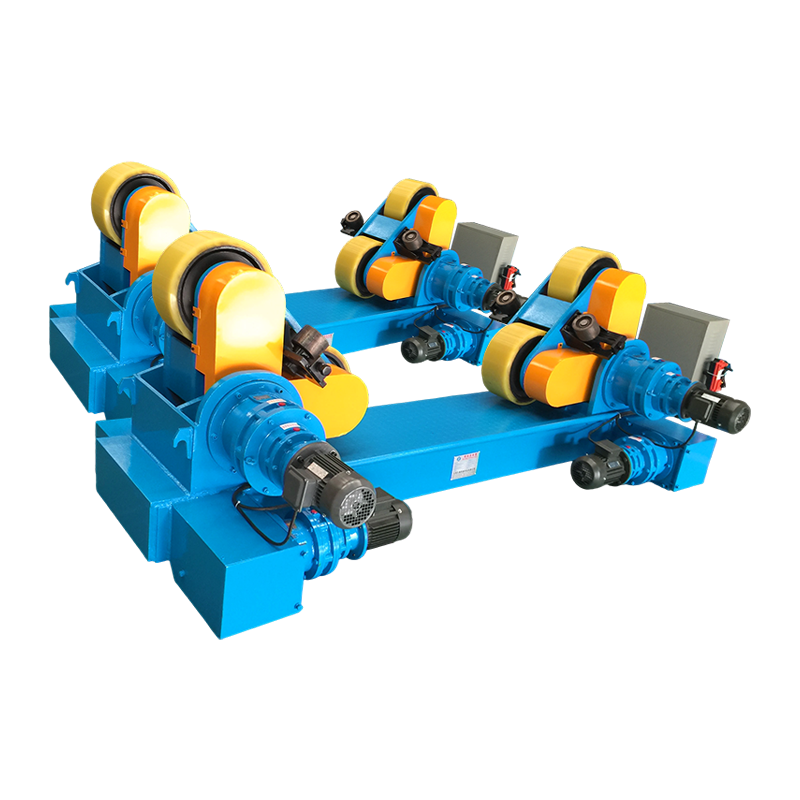

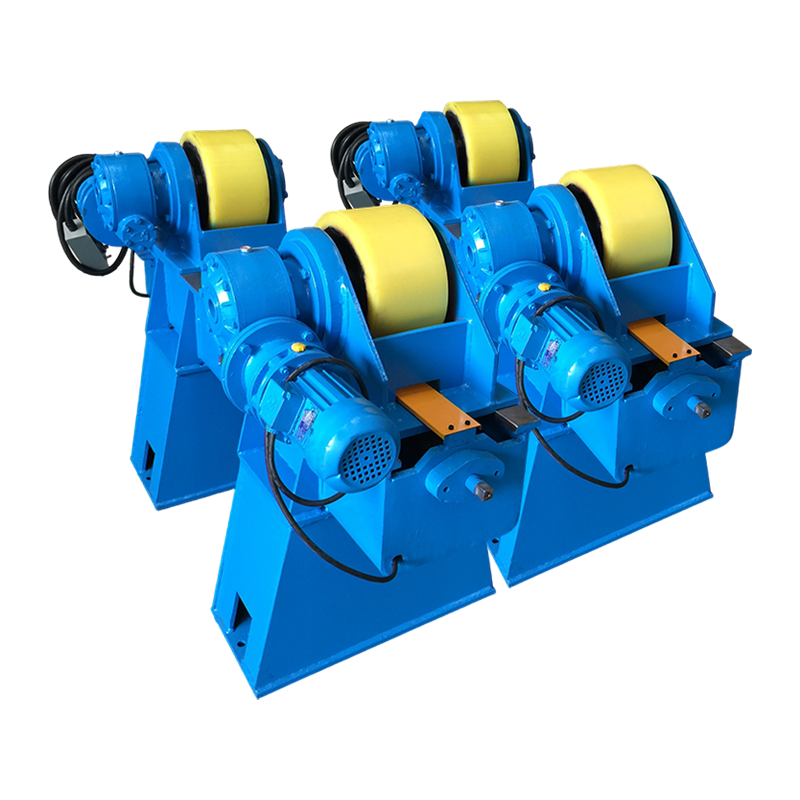

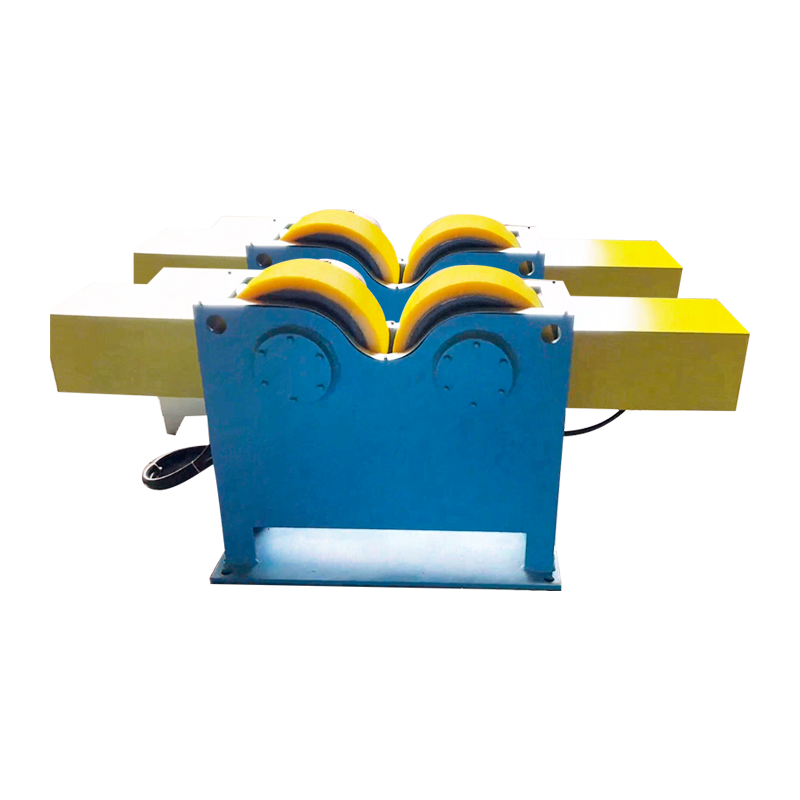

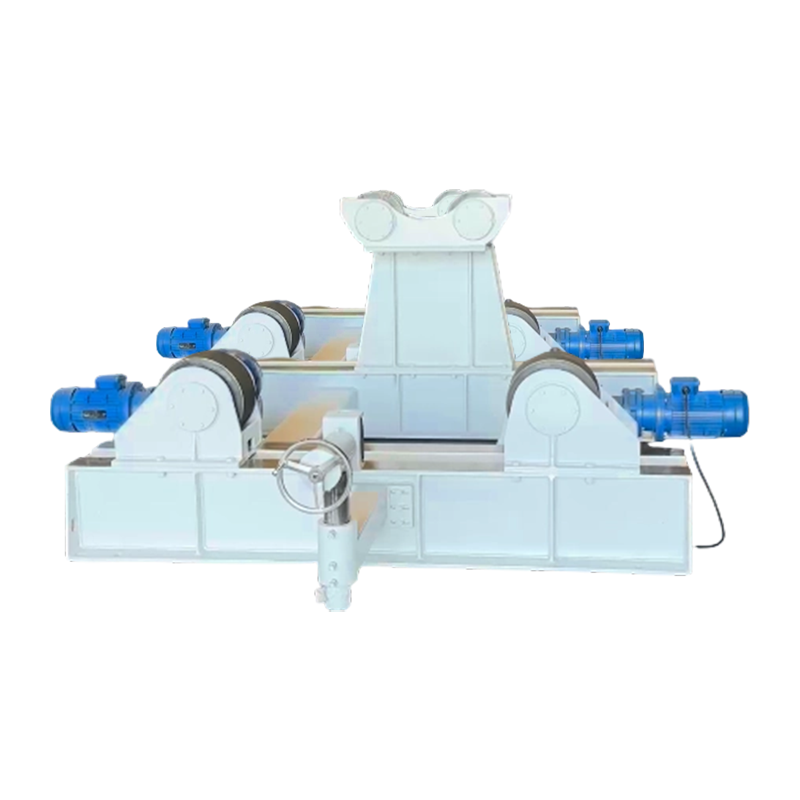

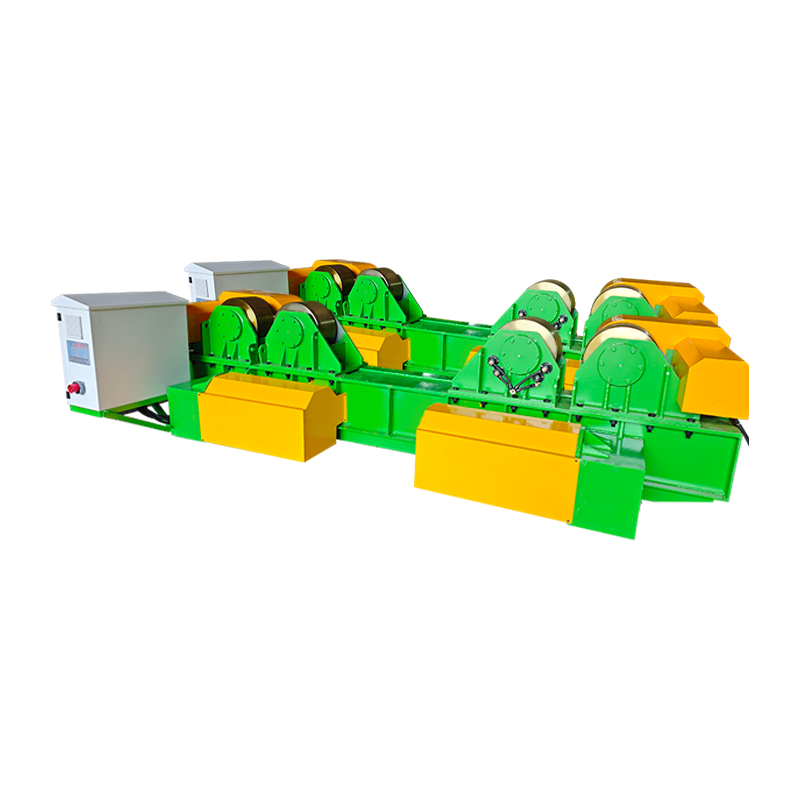

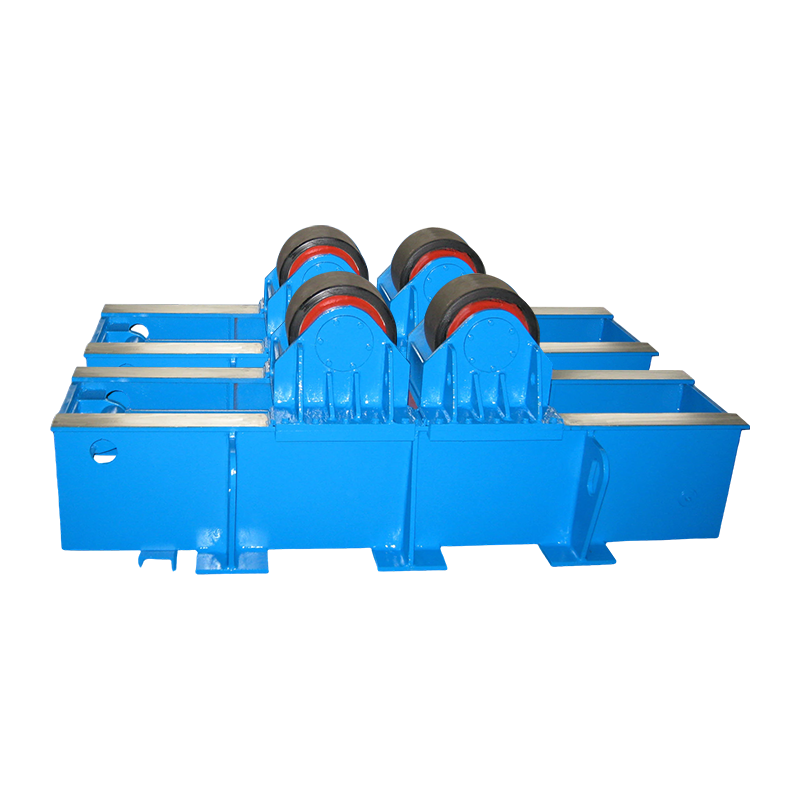

Welding Circumferential Seams: A circumferential (or girth) seam is a circular weld that joins two sections of a pipe or vessel. For this operation, the column and boom work in conjunction with a welding rotator or turning roll. The cylindrical workpiece is placed on the rotator, which slowly and steadily rotates it. The boom is positioned so that the welding torch is fixed at the correct point relative to the rotating seam. As the rotator turns the workpiece, the welding torch remains stationary, creating a perfectly circular weld. The synchronization between the rotator's rotation speed and the welding parameters is key to achieving a high-quality result.

The ability to handle both types of seams with equal precision makes the Welding Manipulator/Welding Column & Boom /Welding Center/Automatic Welding system an incredibly versatile asset in a fabrication shop. It provides a reliable foundation for improving product quality, as the mechanical movements are far more consistent than what can be achieved manually. This repeatability is crucial for meeting stringent industry codes and standards, such as those set by the American Society of Mechanical Engineers (ASME) for pressure vessels.

Tailoring Automation to Specific Needs: The Power of Customization

One of the significant advantages of modern column and boom systems is their adaptability. Manufacturers like WeldNice understand that different applications have unique requirements. Therefore, they support the design of customized functions. This allows a fabricator to configure a system that is precisely suited to their specific production needs. Let's explore some of the advanced options mentioned and their practical benefits.

Enhancing Speed with Tandem Submerged Arc Welding

For applications where speed is a primary concern, such as in the fabrication of thick-walled structures, Tandem Submerged Arc Welding (SAW) is a powerful option. This configuration involves two welding wires being fed through a single welding head or two closely spaced heads. Both wires are energized, either from the same power source or from two separate sources.

How it Works: The lead wire creates the primary weld pool, while the trail wire follows, adding more heat and filler material to the same puddle. This arrangement significantly increases the deposition rate compared to a single-wire setup.

Practical Benefits: The primary advantage is a dramatic increase in welding speed. For a thick plate that might require ten passes with a single wire, a tandem setup might accomplish the same weld in just five or six passes. This translates directly to reduced labor hours, lower energy consumption, and faster project completion. It is an effective solution for high-production environments where time is a critical factor.

Achieving Efficiency in Thick Materials with Narrow-Gap Welding

When welding very thick materials, traditional methods require a wide V-groove bevel. This means a large volume of filler metal must be deposited to fill the joint, which is time-consuming and expensive. Narrow-gap welding is a specialized technique designed to address this.

How it Works: Instead of a wide bevel, a narrow, U-shaped or J-shaped groove is prepared. The joint gap might be only a few millimeters wide. A special welding head and torch are used to direct the arc into the bottom of this narrow groove. The process often involves a weaving or oscillating motion to ensure the sidewalls are properly fused.

Practical Benefits: The benefits are substantial. By reducing the joint volume, the amount of filler metal required can be reduced by 50% or more. This leads to significant cost savings on welding wire and flux. Furthermore, because less heat is put into the workpiece overall, there is reduced distortion and a smaller heat-affected zone (HAZ), which can be beneficial for the mechanical properties of the material. This method is particularly well-suited for thick-walled pressure vessels, reactors, and other heavy-duty components.

Expanding Capabilities with Advanced Features

Beyond specific welding processes, a range of other features can be integrated to enhance the functionality and ease of use of a column and boom system.

Orbital Movement: This feature allows the welding head to move in a circular or orbital path around a fixed point. It is useful for applications like welding pipe-to-fitting connections or other complex joints where a simple linear or circumferential movement is insufficient.

Column Rotation: Some advanced systems offer a rotating column. This allows the entire boom to swing around the base, providing access to different sides of a large or complex workpiece without having to reposition the entire manipulator. This is a valuable feature for large, stationary structures like ship hull sections or building frames.

Servo Motors: The choice of motors for driving the boom and column movements has a direct impact on precision. Servo motors offer a high degree of control over position, speed, and torque. They allow for very accurate positioning of the welding head and can maintain a constant speed under varying load conditions. This level of control is beneficial for critical applications and for integrating with automated seam tracking systems.

Seam Tracking Unit: Even with the most precise fixturing, there can be slight variations in the position of the weld seam due to thermal distortion or manufacturing tolerances. A seam tracking unit uses a sensor (often laser-based) to locate the actual joint in real-time. It then automatically adjusts the position of the welding head to follow the seam perfectly. This feature is invaluable for ensuring consistent weld quality and reducing the need for operator intervention, especially on long or curved seams.

Flux Recycle Unit: In Submerged Arc Welding (SAW), a granular flux is used to protect the weld pool. After welding, this flux can be collected, crushed, and reused. A flux recycle unit automates this process, vacuuming up the used flux, sifting out impurities and slag, and returning the clean flux to a hopper for reuse. This reduces material waste, lowers operating costs, and helps maintain a cleaner work environment.

Oscillator: A weld oscillator is a device that causes the welding torch to perform a side-to-side weaving motion as it travels. This is useful for wider weld grooves, as it ensures proper fusion of the sidewalls and can help control the shape and width of the final weld bead. The speed, width, and dwell time of the oscillation pattern can be precisely programmed.

Strip Surfacing: Also known as cladding, this is a process used to apply a layer of corrosion-resistant or wear-resistant alloy onto the surface of a cheaper base metal. Instead of a wire, a wide strip of metal (e.g., stainless steel) is used as the electrode. A column and boom system equipped for strip surfacing can clad large areas, such as the inside of a pressure vessel, quickly and efficiently, providing a protective layer where it's needed most.

A Comparative Look: Manual vs. Automated Welding Processes

To better illustrate the impact of this technology, consider the following comparison between a traditional manual approach and an automated process using a column and boom system.

| Aspect |

Manual Welding |

Automated Welding with a Column & Boom |

| Consistency & Repeatability |

Varies based on operator skill, fatigue, and comfort. Prone to inconsistencies over long runs. |

Highly consistent and repeatable. The machine follows the programmed path and parameters precisely for the entire duration of the weld. |

| Operator Fatigue |

A significant factor, especially for long welds or in awkward positions. Directly impacts quality and productivity. |

The operator's role shifts from physically performing the weld to monitoring and controlling the process. Physical fatigue is no longer a concern. |

| Welding Speed |

Limited by the operator's physical capabilities. Deposition rates are relatively low. |

Can operate at high, continuous speeds. Advanced processes like Tandem SAW can dramatically increase deposition rates. |

| Safety |

Operator is in close proximity to the arc, fumes, and sparks. Risk of injury from awkward positions is higher. |

Operator can control the process from a safe, remote station. Reduces exposure to hazards like arc flash, fumes, and heat. |

| Material Waste & Rework |

Higher potential for defects, leading to rework. This consumes extra filler material, gas, and labor. |

Lower defect rate due to process stability. Reduces the need for costly and time-consuming rework. |

| Skill Requirement |

Requires a highly skilled manual welder for code-quality work, which can be difficult to find and retain. |

Requires a skilled machine operator/programmer. The skill set is different and can be easier to develop than high-level manual welding proficiency. |

Key Considerations for Selecting a System

For a fabricator considering the investment in a Welding Manipulator/Welding Column & Boom /Welding Center/Automatic Welding system, several factors must be evaluated to ensure the chosen equipment aligns with their production needs. The following table outlines some key parameters to consider.

| Parameter |

Description |

Why It Matters |

| Boom Length |

The horizontal reach of the boom, measured from the column. |

Determines the maximum length of a longitudinal seam that can be welded in a single setup or the maximum diameter of a vessel that can be accessed. |

| Load Capacity |

The weight the boom can support at its maximum extension without excessive deflection. |

Crucial for supporting not just the welding torch, but also heavier accessories like multi-wire torches, seam trackers, or cameras. |

| Column Height |

The vertical travel of the boom saddle. |

Defines the range of heights the welding head can reach, important for accommodating workpieces of different diameters and heights. |

| Control System |

The interface used to program and operate the manipulator (e.g., PLC-based, PC-based). |

A user-friendly control system simplifies setup, reduces programming time, and makes it easier for operators to manage the welding process. |

| Available Options |

The list of customizable features like seam tracking, oscillators, flux recovery, etc. |

Allows the system to be tailored to specific applications, enhancing its capability and return on investment. |

The Path Forward for Modern Fabrication

The integration of automated welding solutions like the column and boom system is no longer a luxury reserved for the largest corporations; it is becoming a necessity for any fabrication shop that aims to remain competitive in today's demanding market. The transition from manual to automated processes addresses the most pressing challenges of the industry: the need for higher quality, greater efficiency, improved safety, and reduced dependency on scarce skilled labor.

By providing a stable, precise, and repeatable platform for welding, these systems empower manufacturers to produce complex metal structures with a level of consistency that is difficult to achieve manually. The ability to customize the equipment with advanced features like tandem welding, narrow-gap capabilities, and intelligent seam tracking further extends its utility, allowing it to solve a wide array of specific fabrication challenges.

As technology continues to evolve, we can expect these systems to become even more intelligent and integrated. Features like remote monitoring, data logging for quality control, and integration with factory-wide management systems are on the horizon. However, the core principle remains the same: to mechanize the complex task of welding, freeing up human operators to focus on oversight, programming, and process optimization. For the manufacturers of tanks, pipes, and pressure vessels, the Welding Manipulator/Welding Column & Boom /Welding Center/Automatic Welding is not just a piece of equipment; it is a strategic investment in quality, productivity, and future-proofing their operations.

English

English русский

русский Español

Español عربى

عربى