The Unspoken Challenge in Every Fabrication Shop

In the bustling world of machine manufacturing, fabrication, and metalwork, efficiency and quality are the cornerstones of a successful business. Yet, a persistent and often-overlooked challenge gnaws at productivity on a daily basis: the static workpiece. For decades, welders and operators have been forced to contort their bodies, reposition heavy materials manually, and work in awkward angles to get the job done. This traditional approach isn't just a matter of inconvenience; it directly impacts project timelines, worker safety, and the final quality of the product. The question on the mind of many forward-thinking shop owners and managers is whether there's a practical, accessible solution to this age-old problem. This article explores that very question, delving into a piece of equipment that is quietly revolutionizing workshops around the globe.

Demystifying the Tool: What Exactly is a Welding Positioner?

At its core, a Welding Positioner/Welding Turntable is a mechanical device designed to hold and manipulate a workpiece. Think of it as a sophisticated, motorized turntable that can not only spin but also tilt. Its primary function is to bring the work to the operator, rather than forcing the operator to go to the work. By doing so, it positions the component in a stable, comfortable, and accessible orientation for the task at hand, whether that's welding, polishing, grinding, or spraying.

The magic lies in its control. Modern positioners offer stepless, or variable, speed adjustment. This means the rotation and tilt can be fine-tuned to the exact speed required for a specific process, allowing for steady, even movement. For a welder, this translates to maintaining a consistent arc and travel speed, which are fundamental ingredients for a high-quality weld. For a polisher, it ensures an even finish without the need to stop and manually move the object. It's a simple concept with profound implications for the workflow of any metalworking operation.

The Core Components and How They Work Together

While designs can vary, a typical welding positioner consists of a few key parts:

- Base: The heavy, stable foundation that anchors the device to the floor, preventing any wobbling or movement during operation.

- Turntable (or Chuck):strong> The flat, circular surface where the workpiece is clamped. It's responsible for the rotational movement.

- Tilting Mechanism: The component that allows the turntable to be angled, usually up to 90 or 120 degrees, enabling access to the underside and sides of the workpiece.

- Drive System: The motor and gearbox that power the rotation and tilting actions, providing the torque and control needed for different load capacities.

- Control Box: The interface where the operator can adjust the speed, direction of rotation, and angle of tilt. This is where the "stepless adjustment" is managed.

Understanding these components helps in appreciating the robustness of the equipment. It's not just a simple spinner; it's a purpose-built machine designed to provide precise, repeatable movement under load.

The Tangible Benefits: Beyond Simple Convenience

The decision to invest in new equipment always comes down to return on investment. A welding positioner isn't just a "nice-to-have" gadget; it delivers a range of concrete benefits that directly impact a company's bottom line and operational capabilities.

1. A Substantial Leap in Productivity

Time is money, and nowhere is this truer than in a fabrication shop. Manual positioning is a time-consuming activity. A welder might spend a significant portion of their day not welding, but instead stopping, unclamping, flipping, and re-clamping a heavy assembly. A positioner eliminates this dead time.

Consider a cylindrical pipe that needs a longitudinal seam weld. Without a positioner, the welder might weld a few inches, stop, manually roll the pipe, and then restart. This start-stop process is inefficient and can compromise weld quality. With a positioner, the pipe is clamped once, and the operator can engage a slow, continuous rotation. They can perform the entire weld in a single, fluid pass. This reduction in "handling time" can lead to a considerable increase in output, often allowing a single operator to complete the work of two in the same timeframe.

2. Marked Improvement in Work Quality

Human anatomy is not designed for welding in awkward positions. Working overhead, in tight corners, or on the floor leads to fatigue, which in turn leads to inconsistencies. shaky hands, inconsistent travel speed, and poor arc control can result in weld defects like porosity, lack of fusion, or poor bead appearance.

A Welding Positioner/Welding Turntable allows the operator to position the joint in a flat or horizontal position—the "downhand" position. This is the easiest, fastest, and most comfortable position to weld in. It allows for better control of the welding torch and a clearer view of the weld puddle. The result is a more uniform, stronger, and aesthetically pleasing weld. This consistency is crucial for industries with strict quality codes and can significantly reduce the amount of rework needed, saving both time and materials.

3. A Focus on Operator Safety and Ergonomics

Workplace safety is not just a legal requirement; it's a moral and financial imperative. Manual handling of heavy and cumbersome workpieces is a leading cause of musculoskeletal injuries in the fabrication industry. Back strains, shoulder injuries, and repetitive stress disorders are common and can lead to lost workdays and increased insurance costs.

By mechanizing the positioning process, a positioner directly addresses these risks. The operator remains in a fixed, comfortable position, reducing physical strain and fatigue. This not only prevents injuries but also improves overall job satisfaction and morale. A safer, less fatigued worker is a more focused and productive worker. This ergonomic benefit is one of the most compelling arguments for integrating positioners into a modern workshop.

4. Enabling and Enhancing Automation

The rise of robotic welding is transforming the industry. However, a welding robot is only as good as the tooling that presents the part to it. A robot arm has a limited range of motion. To effectively weld a complex, three-dimensional object, the part itself must move.

Welding positioners are the perfect partners for robotic welding cells. They can be synchronized with the robot's movements, turning and tilting the part to present the exact seam needed for the next weld pass. This integration unlocks the full potential of automation, allowing for lights-out operation and the production of complex assemblies with a level of speed and consistency that is impossible to achieve manually. Even for shops not yet ready for full robotics, a positioner is a future-proof investment that lays the groundwork for later automation.

Finding the Right Fit: Applications Across Industries

The versatility of welding positioners means they are not confined to a single niche. Their value is recognized across a diverse spectrum of industries where metal joining and fabrication are key.

Common Applications

- Structural Steel Fabrication: Welding columns, beams, and trusses where consistent, full-penetration welds are critical for structural integrity.

- Pressure Vessel and Tank Manufacturing: Positioning large, cylindrical shells for the welding of longitudinal and circumferential seams.

- Automotive and Aerospace: Assembling components like exhaust systems, frames, and engine parts where precision and repeatability are paramount.

- Heavy Equipment Manufacturing: Building components for agricultural machinery, construction equipment, and mining trucks.

- Furniture and Decorative Metalwork: Creating intricate and high-quality welds on items like tables, railings, and artistic sculptures.

- General Repair and Maintenance: Even in smaller job shops, a positioner can make repairing broken parts faster and result in a more durable fix.

A Buyer's Guide: Key Considerations Before You Invest

Not all welding positioners are created equal. Selecting the right one for your specific needs requires careful consideration of several factors. Making an informed choice will ensure you get a piece of equipment that serves you well for years to come.

1. Workpiece Capacity: Weight and Size

This is the most critical factor. You need a positioner that can safely handle your heaviest and largest workpieces. Always check the manufacturer's specified load capacity (in kilograms or pounds). It's good practice to choose a positioner with a capacity that exceeds your typical maximum load by a comfortable margin. This provides a safety buffer and ensures the machine isn't operating at its absolute limit, which can shorten its lifespan. Also, consider the center of gravity of your parts. An off-center load can put more strain on the positioner than a centrally located one of the same weight.

2. Range of Motion: Rotation and Tilting

How much movement do you need? A basic turntable only provides 360-degree rotation on a horizontal plane. For more complex parts, you'll need a tilting positioner. Check the maximum tilt angle (e.g., 90°, 120°). A 120-degree tilt offers more versatility, allowing you to flip a part almost completely over. Some advanced positioners offer powered tilting, while others have a manual tilt that is locked in place. Your choice depends on how frequently you need to change the tilt angle during a single operation.

3. Speed Control and Precision

The ability to control the rotation speed is essential. For welding, you need a slow, steady, and consistent speed. For polishing or grinding, you might need a faster speed. Look for a positioner with a wide speed range and, importantly, a "stepless" variable speed control. This allows for fine-tuning, not just a selection of a few preset speeds. A foot pedal control can also be a valuable addition, allowing the operator to adjust the speed hands-free for greater control.

4. Power Source and Construction

Most positioners are electrically powered, but you should check the voltage requirements to ensure they match your shop's supply. The construction of the positioner itself is a good indicator of its durability. Look for heavy-duty steel construction, quality bearings, and a robust gearbox. A well-built machine will have less vibration, which contributes to a better finish and longer tool life. The quality of the chuck or clamping mechanism is also important—it needs to hold the workpiece securely without marring it.

| Comparison of Common Welding Positioner Types |

| Type |

Primary Motion |

Best For |

Limitation |

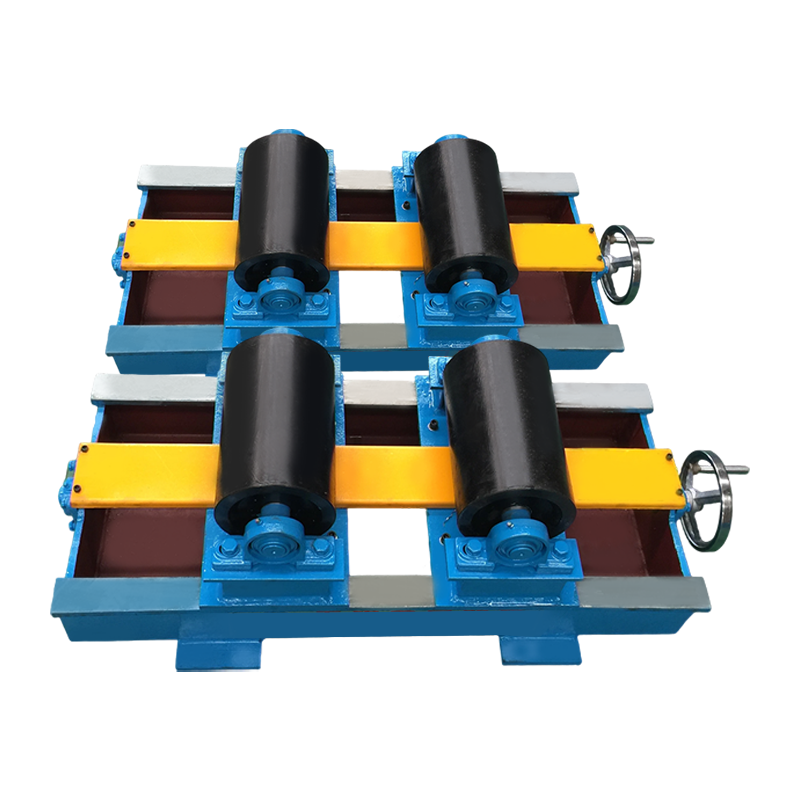

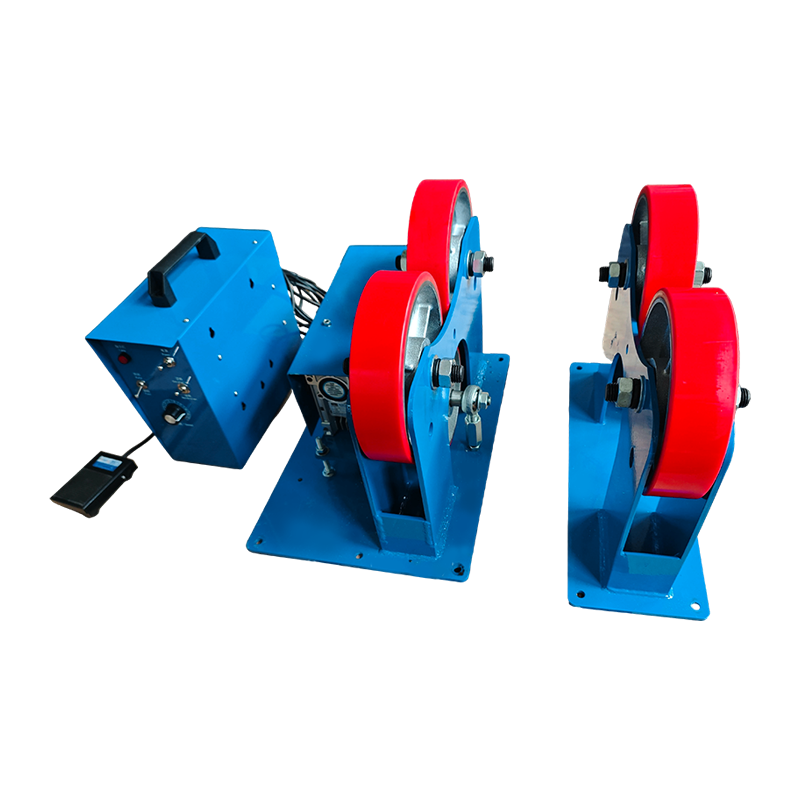

| Turntable Positioner |

Horizontal 360° rotation only. |

Cylindrical parts, circular seams, flanges. |

Cannot access the underside or sides of a part without manual repositioning. |

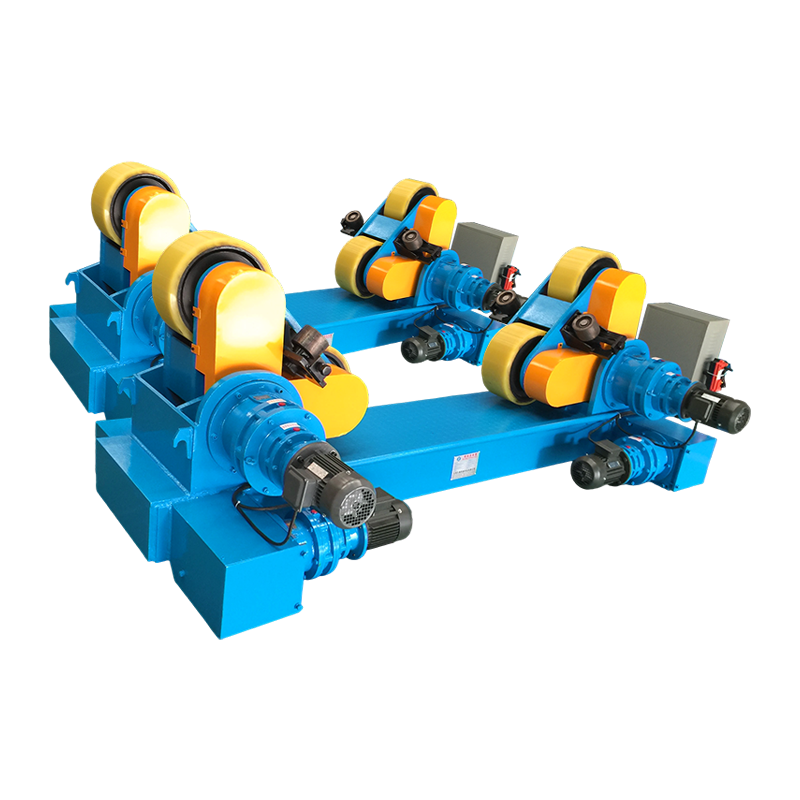

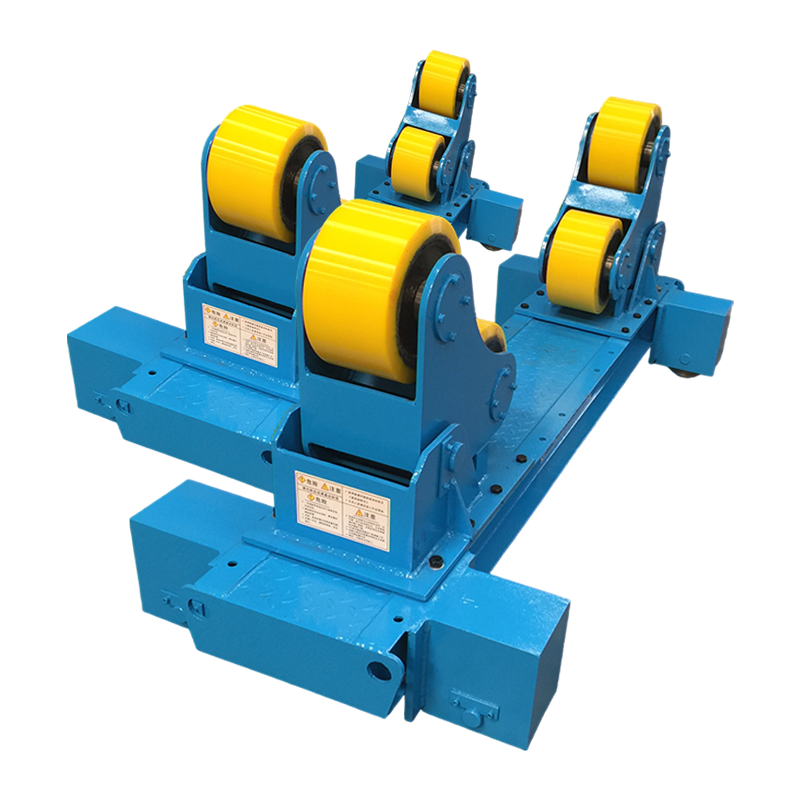

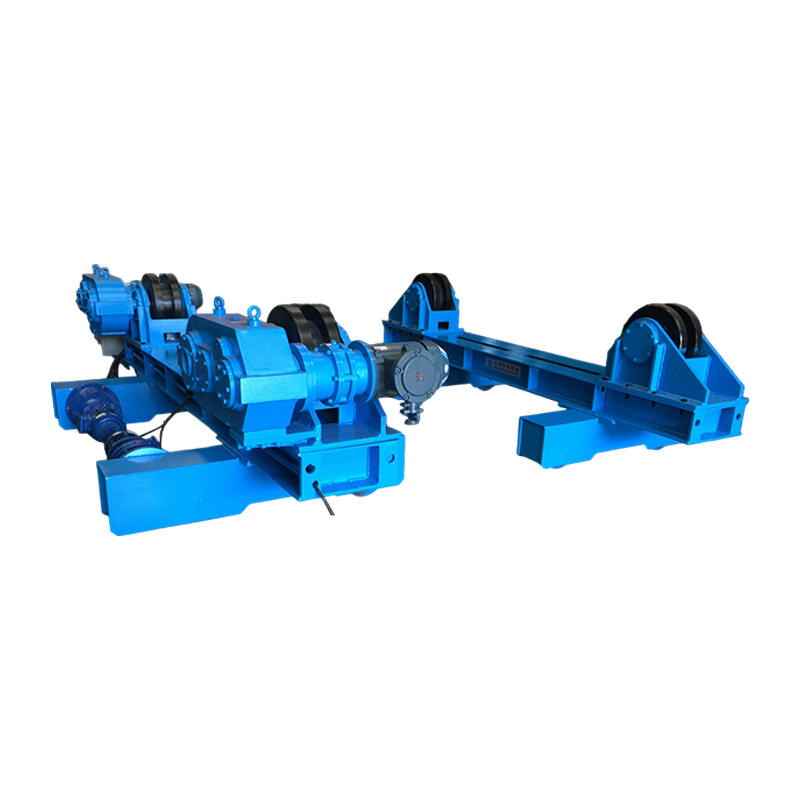

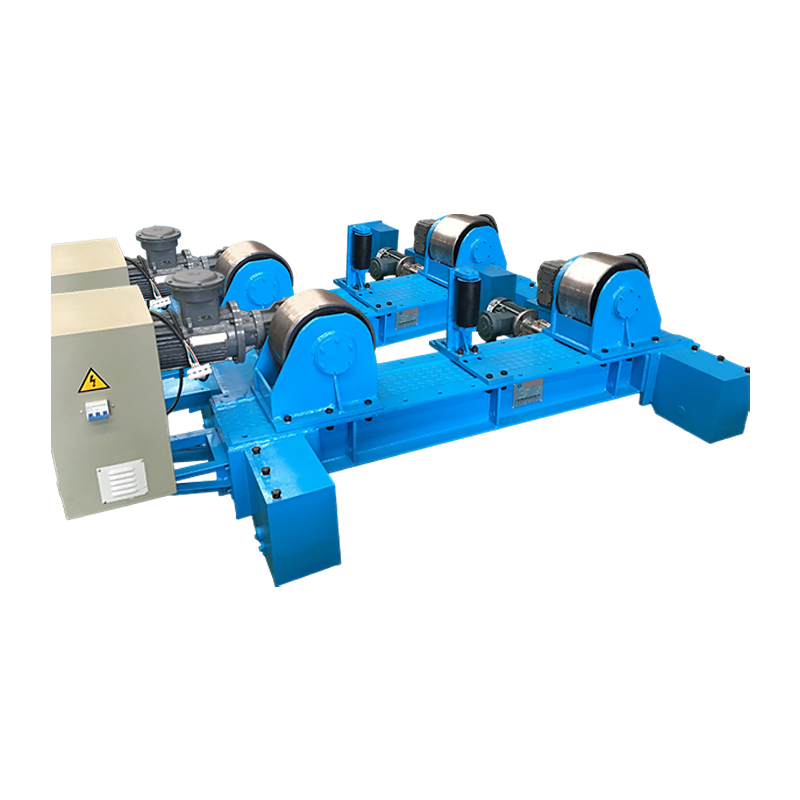

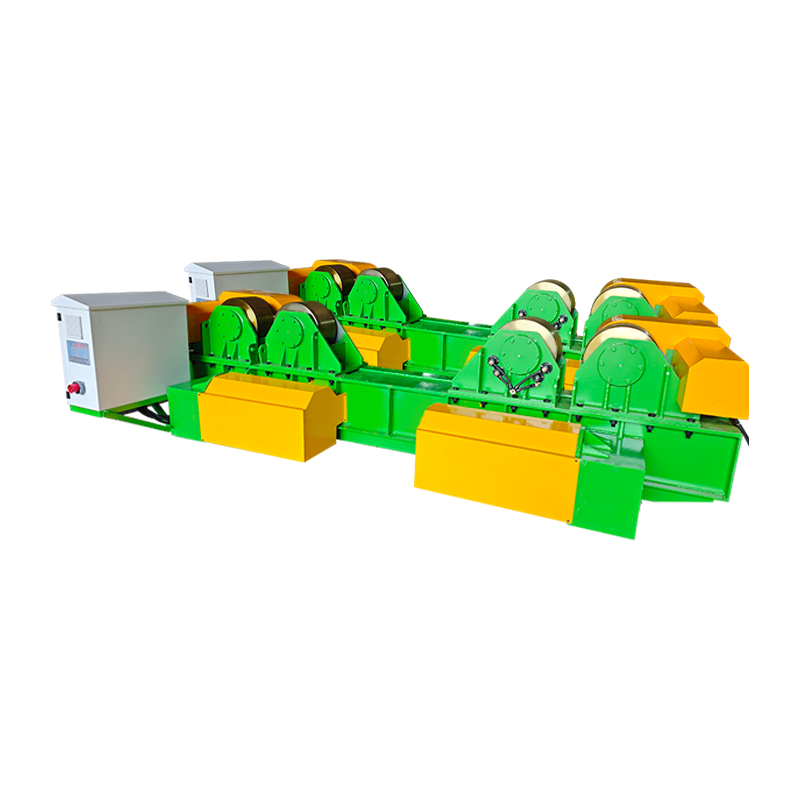

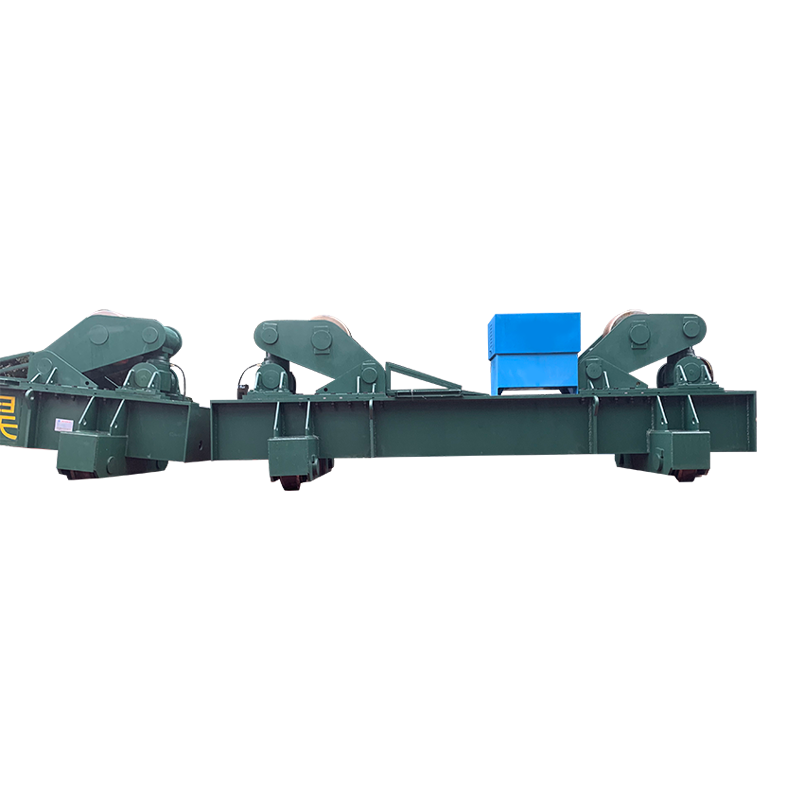

| Head & Tail Stock Positioner |

Horizontal rotation between two chucks. |

Long, cylindrical parts like shafts, pipes, and tubes. |

Less suitable for short or irregularly shaped parts. |

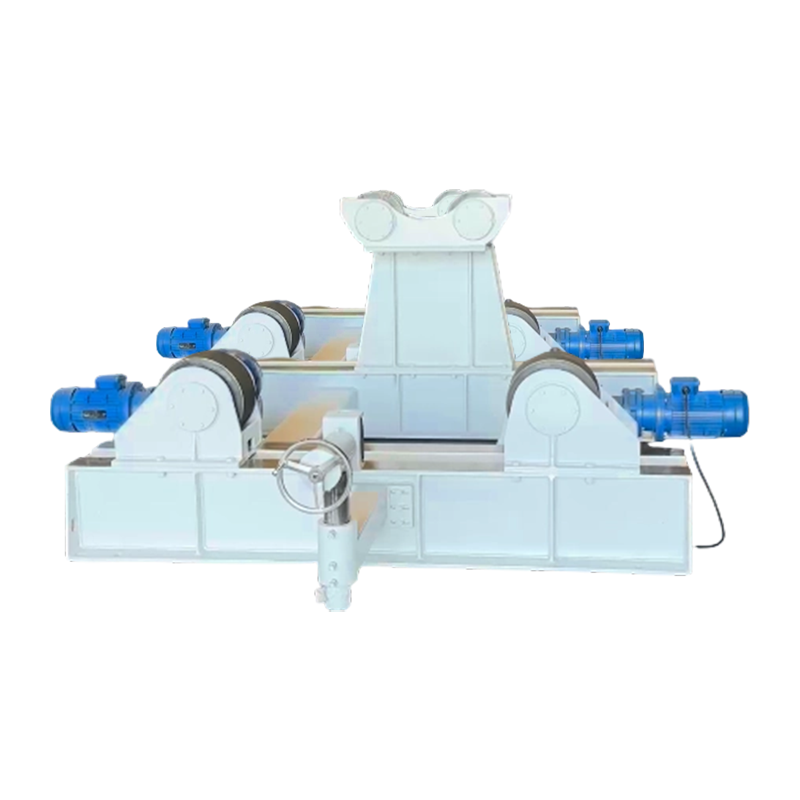

| Tilt & Turn Positioner |

360° rotation + tilting up to 120°. |

Complex, 3D parts; general fabrication; robotic welding integration. |

Generally more expensive and has a lower load capacity than a similarly sized turntable. |

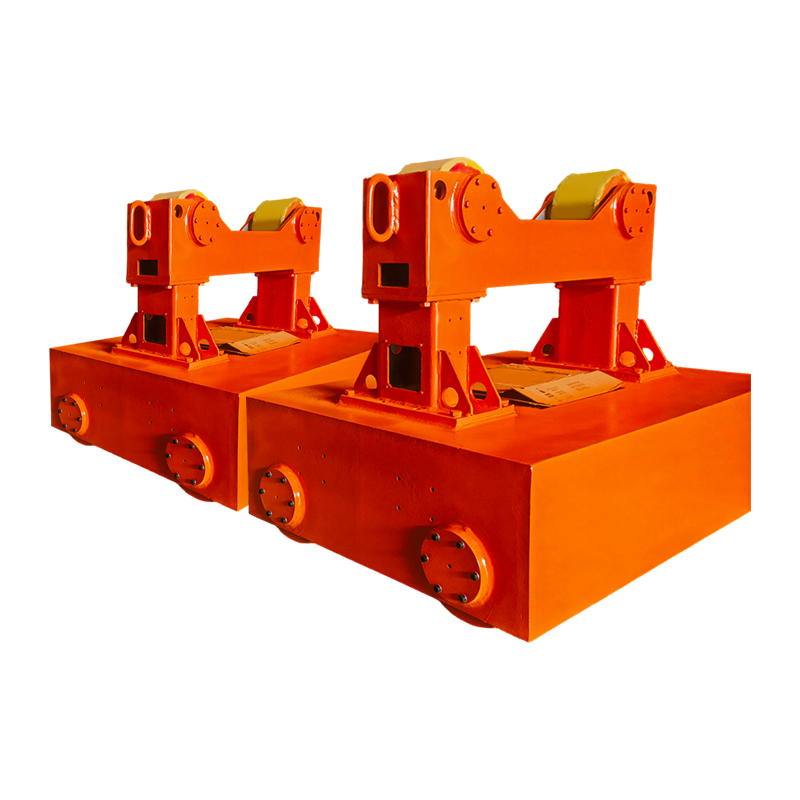

| Positioning Turntable |

Often refers to a heavier-duty, industrial-grade tilt & turn unit. |

Heavy-duty applications in shipbuilding, pressure vessel manufacturing. |

Higher cost, requires significant floor space. |

Implementing a Positioner in Your Workflow

Purchasing the equipment is only the first step. To reap the full benefits, proper implementation is key. This involves training, safety procedures, and maintenance.

Training Your Team

Even though a positioner is designed to be easy to operate, proper training is essential. Operators should understand the machine's controls, its load limits, and safe clamping procedures. They should be trained on how to secure different types of workpieces to the turntable effectively. A well-trained operator will not only work more efficiently but will also be less likely to cause damage to the machine or the workpiece through misuse.

Establishing Safety Protocols

As with any moving machinery, safety is paramount. Establish clear safety protocols, which should include:

- Ensuring the workpiece is securely clamped before starting the rotation.

- Keeping hands, loose clothing, and long hair away from moving parts.

- Performing regular checks of the machine's safety features.

- Understanding the emergency stop procedure.

Regular Maintenance for Longevity

A welding positioner is a mechanical device that requires maintenance to operate reliably. Consult the manufacturer's manual for a recommended maintenance schedule. This typically includes checking for loose bolts, cleaning debris from the turntable and gears, and lubricating moving parts. A small investment in preventative maintenance can prevent costly downtime and extend the life of your equipment significantly.

The Future is Automated: Positioners as a Cornerstone of Industry 4.0

The conversation in manufacturing is increasingly dominated by Industry 4.0, the Internet of Things (IoT), and the smart factory. In this context, the humble welding positioner takes on a new and exciting role. It is no longer just a standalone tool but an integral node in a connected, automated production line.

Future-ready positioners are being designed with advanced controls that can communicate directly with robotic arms and central factory management systems. Imagine a scenario where a CAD model of a part is automatically translated into welding instructions. The system then directs a robot to pick up the part, place it on a positioner, and then orchestrates a synchronized dance between the robot's welding torch and the positioner's movement to complete the assembly without any human intervention. The positioner provides feedback on its position, speed, and torque, allowing for real-time adjustments and quality control.

Investing in a high-quality, versatile Welding Positioner/Welding Turntable today is a step toward this future. It's an investment in a flexible platform that can adapt as your business grows and embraces new technologies. The positioners produced by companies like WeldNice, with their focus on advanced structure and complete functionality, are built with this kind of adaptability in mind, providing a reliable foundation for both current needs and future ambitions.

Conclusion: A Strategic Investment for a Competitive Edge

The question posed at the beginning of this article—"Is the welding positioner the answer for modern workshops?"—can be answered with a resounding yes. The challenges of inefficiency, inconsistent quality, and workplace safety are not minor inconveniences; they are significant barriers to growth and profitability. The welding positioner directly addresses these barriers in a practical and impactful way.

By bringing the work to the operator, it streamlines workflows, enhances the quality of the final product, and creates a safer, more ergonomic working environment. It serves as a crucial enabler for automation, positioning businesses to compete in an increasingly technology-driven market. While the initial investment may require consideration, the long-term returns in productivity, quality, and operator well-being make it a strategic decision for any fabrication or manufacturing operation looking to build a durable and competitive advantage. It's not just about solving today's problems; it's about building a foundation for tomorrow's success.

English

English русский

русский Español

Español عربى

عربى