In heavy-duty industries such as energy equipment manufacturing and large-scale pressure vessel fabrication, the primary challenge is not just the weld itself, but the safe and precise manipulation of the workpiece. A 15T Conventional Welding Positioner is a heavy-duty powerhouse designed to handle...

READ MORETIG Column & Boom Manufacturer

TIG Column & Boom is an important supporting equipment for Tungsten Inert Gas Welding (TIG); it can accurately adjust the position and angle of the welding torch, control the welding travel and oscillation trajectory, and assist in adapting to the argon protection environment, which ensures the forming quality and precision of welding for thin-walled and precision components, improves operation efficiency and reduces manual labor intensity.

information to be updated

-

-

In the realm of machinery manufacturing and pressure vessel production, the ability to maintain a consistent welding angle is often the difference between a high-strength joint and a costly defect. The 100KG Conventional Welding Positioner is engineered as a universal solution for these high-precis...

READ MORE -

In the fabrication of boilers and pressure vessels, the ability to rotate cylindrical workpieces with precision is the difference between a high-integrity weld and a structural failure. The Welding Rotator (also known as a Welding Turning Roller or Roller Frame) is an essential specialized tool for...

READ MORE

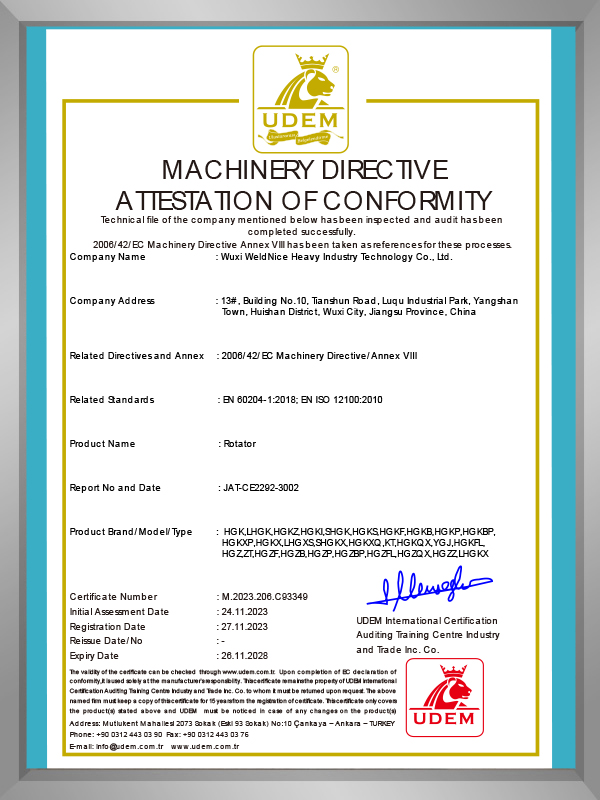

As a core component of Tungsten Inert Gas (TIG) welding equipment, the TIG welding column and arm are crucial for ensuring efficient precision welding. Their core advantage lies in their ability to precisely adjust the welding torch's position and angle, accurately control the welding path and oscillation trajectory, and simultaneously adapt to the argon protective environment. This core advantage makes them essential equipment for welding thin-walled parts and precision components. Wuxi Wildenness Heavy Industry Technology Co., Ltd. (hereinafter referred to as Wildenness), a professional welding equipment manufacturer established in 2004, relies on advanced production and processing equipment, testing equipment, and a comprehensive quality assurance system. Wildenness's TIG welding columns and arms have achieved breakthroughs in both stability and precision. They not only effectively guarantee the quality and precision of weld formation but also significantly improve operational efficiency and reduce manual labor intensity, providing high-quality products suitable for various scenarios for numerous users both domestically and internationally. The core value of TIG welding stations and arms has led to a continuous increase in demand for them in the precision manufacturing field, making them one of the important indicators for measuring the degree of automation and precision in welding operations.

I. Core Common Features of Our Products

Leveraging nearly 20 years of experience in welding equipment, WeldNice, based on a deep understanding of the welding needs of various industries, has developed and produced a series of TIG welding stations and booms. These products share the following advantages, meeting the core requirements of most precision welding scenarios:

- Precise Adjustment Capability: Utilizing a high-precision transmission structure design, it enables precise positioning of the welding torch in three-dimensional space. The angle adjustment range covers ±180°, and the position adjustment accuracy reaches 0.1mm, meeting the stringent positioning error requirements for precision parts welding;

- Trajectory Control Advantages: Supports customizable welding speeds (0.1-50mm/s) and oscillation trajectories (sine wave, sawtooth wave, etc.), and can be flexibly adjusted according to the workpiece welding type (straight seam, circumferential seam, etc.) to ensure consistent weld formation;

- Argon Gas Protection Adaptability: The equipment has a specially designed argon gas tube fixing structure, which can be used in conjunction with the welding torch to achieve precise guidance of argon gas protection. While reducing argon gas consumption, it ensures the stability of the inert gas atmosphere in the welding area, avoiding defects such as weld oxidation and porosity at high temperatures;

- High efficiency and adaptability: Adopting a modular design, it can be flexibly matched with welding workbenches of different tonnages and different models of TIG welding machines to meet various welding needs, from small precision parts to medium-sized thin-walled parts. Furthermore, installation and commissioning are convenient, greatly shortening the equipment commissioning cycle.

II. Working Principle

The core working principle of the TIG column arm is to achieve precise control of the relative position, angle, and movement trajectory between the welding torch and the workpiece through the coordinated operation of the mechanical structure. Simultaneously, in conjunction with the argon gas protection mechanism of TIG welding, it ensures the stability of the welding process. Its specific principle can be divided into three core components:

1. Positioning and Drive Component: Through the lifting and lowering motion of the column and the telescopic and rotating motion of the arm, the welding torch is driven to adjust its position in three-dimensional space. The drive system uses a combination of servo motors and high-precision ball screws to ensure the stability of the movement process and positioning accuracy. WeldNice employs an independently optimized transmission ratio design in this stage, further reducing positioning errors;

2. Trajectory Control: A programmable control system presets parameters such as welding travel speed, oscillation frequency, and oscillation amplitude. This system provides real-time feedback on the welding torch's movement status and dynamically corrects its trajectory, preventing weld deviations caused by workpiece placement errors or equipment vibrations;

3. Protective Adaptive System: The equipment integrates an argon gas tube fixing and guiding structure. As the welding torch moves, the argon gas tube moves synchronously, ensuring the argon gas outlet is always aligned with the molten pool area, forming a stable inert gas protective shield that isolates air from contact with the molten pool, thereby guaranteeing weld quality.

III. Application Scenarios

With its superior welding control characteristics, TIG column-mounted welding equipment is widely used in industries with extremely high welding quality requirements. WeldNice provides customized equipment solutions tailored to the specific process characteristics of each industry. The following are typical application scenarios and case studies:

1. Typical Application Scenarios

- Aerospace: Welding of precision components (such as aircraft engine blades, thin-walled fuselage connectors);

- Medical Devices: Aseptic welding of stainless steel medical devices (such as surgical instruments, medical containers);

- Electronic Equipment: Welding of thin-walled components (such as precision electronic components, lithium battery casings);

- Automotive Manufacturing: Precision welding of key components such as new energy vehicle battery packs and motor casings;

- Chemical Equipment: Welding of corrosion-resistant stainless steel chemical pipelines and containers.

IV. Comparison Between TIG Column & Boom and Traditional Welding Auxiliary Equipment

|

Comparison Dimension

|

TIG Column & Boom (WeldNice)

|

Traditional Manual Welding Torch Holding

|

Simple Welding Bracket

|

|

Positioning Precision

|

0.1mm, precise control of angle and position

|

Depends on manual operation, error ≥2mm

|

Fixed position, low adjustment precision, error ≥1mm

|

|

Welding Efficiency

|

Continuous operation available, efficiency increased by 2-3 times

|

Manual operation is prone to fatigue, low efficiency and large fluctuation

|

Manual adjustment of workpiece/bracket required, general efficiency

|

|

Weld Quality Stability

|

Qualification rate ≥99%, uniform forming, no oxidation defects

|

Qualification rate 60%-75%, prone to oxidation and porosity

|

Qualification rate 70%-80%, general stability

|

|

Argon Protection Effect

|

Special guiding structure, stable protective cover, low loss

|

Manual control, easy deviation of protection range, high loss

|

No special guidance, poor protection effect

|

|

Adaptable Scenarios

|

Thin-walled parts, precision components, multiple types of welds

|

Simple welds, scenarios with low precision requirements

|

Fixed model workpieces, mainly straight seam welding

|

|

Manual Labor Intensity

|

Automatic control, low labor intensity

|

High-intensity hand-held operation, high labor intensity

|

Manual adjustment required, medium labor intensity

|

V. Maintenance Guidelines

1. Daily Maintenance (Daily/Weekly)

-

Clean dust and welding slag on the equipment surface and transmission structures (column, boom, guide rail, etc.) to avoid impurities affecting movement precision;

-

Check the operation status of the servo motor and drive system to ensure no abnormal noise or heating;

-

Check whether the argon pipe is damaged or leaking, and whether the fixing structure is firm, and replace damaged parts in time;

-

Apply special lubricating oil to transmission parts such as guide rails and ball screws to ensure smooth movement.

2. Regular Maintenance (Monthly/Quarterly)

-

Comprehensively test the positioning precision of the equipment, calibrate it with professional instruments, and adjust the transmission structure parameters in time if there is deviation;

-

Check the program parameters of the control system, back up key data, and ensure stable operation of the system;

-

Check the circuit connections and terminals of the equipment to avoid faults caused by loosening or aging;

-

Comprehensively inspect wearing parts (such as bearings and sealing rings) and replace aging parts in time.

3. Special Maintenance (Shutdown/Seasonal Change)

-

When the equipment is shut down for a long time, clean all parts of the equipment, apply anti-rust oil, cover with a dust cover, and avoid moisture and dust erosion;

-

During seasonal changes (especially in high-temperature and low-temperature environments), check the heat dissipation/anti-freezing system of the equipment to ensure it adapts to changes in ambient temperature.

English

English русский

русский Español

Español عربى

عربى