In heavy-duty industries such as energy equipment manufacturing and large-scale pressure vessel fabrication, the primary challenge is not just the weld itself, but the safe and precise manipulation of the workpiece. A 15T Conventional Welding Positioner is a heavy-duty powerhouse designed to handle...

READ MOREL-Type Welding Positioner Manufacturer

1 L-type welding positioner is usually equipped with rotation and tilting functions, thus the fixed workpiece gets desired posture. Usually rotation function is VFD and tilting function is constant speed.

information to be updated

-

-

In the realm of machinery manufacturing and pressure vessel production, the ability to maintain a consistent welding angle is often the difference between a high-strength joint and a costly defect. The 100KG Conventional Welding Positioner is engineered as a universal solution for these high-precis...

READ MORE -

In the fabrication of boilers and pressure vessels, the ability to rotate cylindrical workpieces with precision is the difference between a high-integrity weld and a structural failure. The Welding Rotator (also known as a Welding Turning Roller or Roller Frame) is an essential specialized tool for...

READ MORE

In modern heavy-duty welding manufacturing, precise workpiece positioning is crucial for ensuring weld quality, improving production efficiency, and reducing operator fatigue. The L-Type Welding Positioner is a core fixturing device engineered specifically for this purpose. As a key component of automated welding lines, the L-Type Welding Positioner utilizes its robust mechanical structure and precise motion control to maneuver workpieces fixed to its table into the optimal welding orientation. This ensures that welds are consistently performed in the flat or horizontal-vertical (ship) position, significantly enhancing weld consistency, penetration depth, and bead appearance.

Core Functionality & Operating Principle

The L-Type Welding Positioner typically features a classic "L"-shaped configuration with two primary axes of motion:

-

Rotation Axis (Main Axis): Drives the worktable for continuous 360° rotation. This function is commonly powered by a Variable Frequency Drive (VFD), enabling stepless speed control to meet the precise requirements of different welding processes and ensure uniform, stable circumferential welds.

-

Tilting Axis (Secondary Axis): Drives the "L"-arm and worktable in a forward/backward tilting motion, typically through a range of 0° to 135° or more. This function often operates at a constant speed, providing reliable angular positioning for optimal workpiece orientation.

The coordinated movement of these two axes allows large, heavy workpieces to be repositioned flexibly in space, transforming complex multi-positional welds into simpler flat or horizontal fillet welds. This is fundamental for achieving high-quality, repeatable welding results.

Key Applications & Industry Use Cases

L-Type Positioners are extensively used across various heavy industries:

| Industry | Typical Workpieces | Role & Value |

|---|---|---|

| Construction Machinery | Excavator booms, frames, swing rings | Enables flat-position welding on large structural components, ensuring the strength of critical load-bearing joints. |

| Pressure Vessels | Tank shells, heads, nozzle connections | Facilitates automated all-position welding for circumferential/longitudinal seams and various pipe attachments. |

| Wind Power & Energy | Tower flanges, gearbox housings, bases | Ensures roundness and concentricity in large annular component welding, minimizing distortion. |

| Rail Transportation | Bogie frames, car body underframes | Improves positioning accuracy and welding efficiency in batch production, ensuring operational safety. |

| Shipbuilding | Small sub-assemblies, hatch covers, ribs | Allows for prefabrication of components in the workshop, improving working conditions and build quality. |

Key Selection Parameters: A Comparative Guide

Selecting the right L-Type Welding Positioner requires careful consideration of several core parameters:

| Parameter | Light-Duty Series | Standard Series | Heavy-Duty/Custom Series | Notes & Recommendations |

|---|---|---|---|---|

| Rated Load Capacity (kg) | 500 - 3,000 | 3,000 - 20,000 | 20,000+ | Determine based on maximum combined weight of workpiece and fixture, including a safety margin. |

| Table Size (mm) | Φ800 - Φ1500 | Φ1500 - Φ3000 | Custom-built | Must accommodate workpiece dimensions and ensure clamping stability. |

| Tilting Range | 0° - 135° | 0° - 135° | ±180° (Optional) | Must meet the required flipping range for the workpiece. |

| Drive System | VFD Rotation + Constant Tilt | VFD Rotation + Constant/VFD Tilt | Full Servo Control | VFD/Servo control allows for smoother acceleration/deceleration and speed adjustment, ideal for precision welding. |

| Positioning Accuracy | Standard | Standard | High-Precision | Critical for robotic welding or high-accuracy applications. |

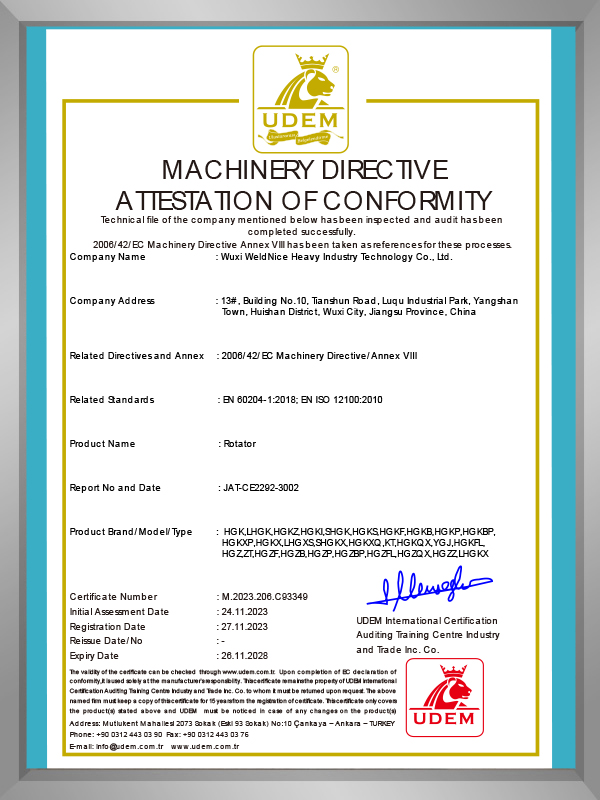

With nearly two decades of specialization in welding fixture technology, Wuxi WeldNice Heavy Industry Technology Co., Ltd. possesses a deep understanding of heavy equipment manufacturing demands. Our L-Type Welding Positioner series offers distinct advantages, including:

-

Superior Structural Rigidity: Optimized via Finite Element Analysis (FEA) to ensure long-term, stable operation under full load without deformation or vibration.

-

Stable Motion Control: Incorporates branded electrical components and proven drive solutions for smooth operation and accurate positioning.

-

Strong Customization Capability: We provide comprehensive customization—from worktable design and fixture interfaces to control system integration—tailored to your specific workpiece, welding process, and production line requirements.

Frequently Asked Questions (FAQ)

Q: What is the main difference between an L-Type Positioner and a Headstock-Tailstock Positioner?

A: An L-Type Positioner is a single-sided unit integrating both rotation and tilt functions, offering a compact design ideal for medium-to-large box-type or frame workpieces. A Headstock-Tailstock Positioner supports and rotates long, shaft-like workpieces from both ends, making it suitable for elongated cylinders, pipes, or beams. The choice depends primarily on workpiece geometry and clamping method.

Q: How is the load capacity for a positioner determined?

A: The required load capacity must exceed the total combined weight of the workpiece and all associated fixtures. We recommend incorporating a safety factor of approximately 30% to account for dynamic loads and ensure long-term operational stability. WeldNice engineers can assist you in performing precise calculations and selection.

Q: Can the positioner be integrated with my existing welding robot or automated system?

A: Yes. Our L-Type Welding Positioners come standard with communication interfaces (e.g., DeviceNet, Profibus, Ethernet/IP) compatible with major robot brands, supporting coordinated motion for true flexible automated welding cells.

Maintenance & Service Guidelines

To ensure the long-term reliability and performance of your L-Type Welding Positioner, we recommend the following maintenance practices:

-

Daily Checks: Inspect for loose bolts or fasteners; keep guideways, gears, and other moving parts clean.

-

Scheduled Lubrication: Strictly follow the manual's schedule to apply the specified grade of grease or oil to key components such as slewing bearings, gear reducers, and gear sets.

-

Electrical System: Periodically check the tightness of electrical terminals and remove dust from the control cabinet to ensure proper heat dissipation.

-

Extended Downtime: For long-term storage, clean the equipment, apply anti-rust treatment to exposed metal surfaces, and power on the system periodically for a brief run.

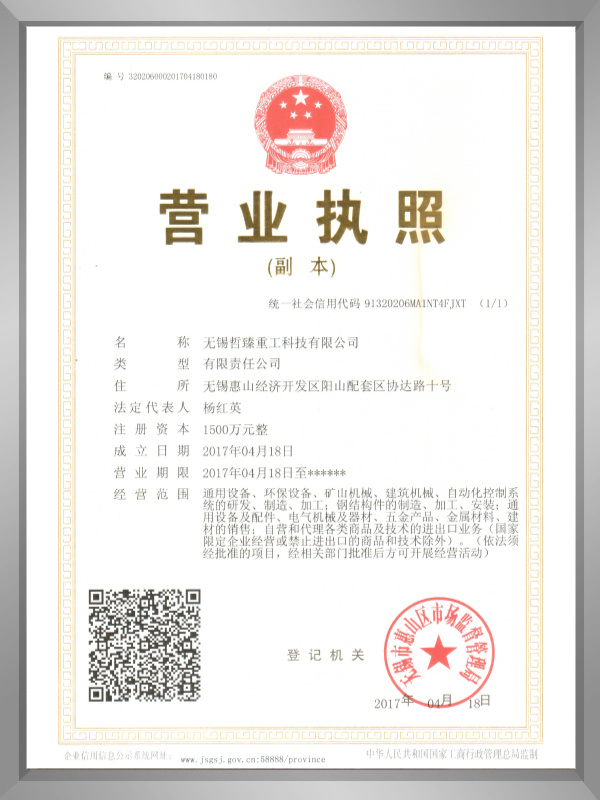

Choosing Wuxi WeldNice Heavy Industry Technology Co., Ltd. means partnering with a reliable expert in welding solutions, not just acquiring a high-performance L-Type Welding Positioner. Located in the economically vibrant and well-connected region of Wuxi's Huishan District, we leverage advanced manufacturing and testing equipment, supported by a rigorous quality management system. We are committed to providing global clients with robust, durable heavy-duty welding positioning equipment, empowering your journey toward smarter, more efficient manufacturing.

English

English русский

русский Español

Español عربى

عربى