In heavy-duty industries such as energy equipment manufacturing and large-scale pressure vessel fabrication, the primary challenge is not just the weld itself, but the safe and precise manipulation of the workpiece. A 15T Conventional Welding Positioner is a heavy-duty powerhouse designed to handle...

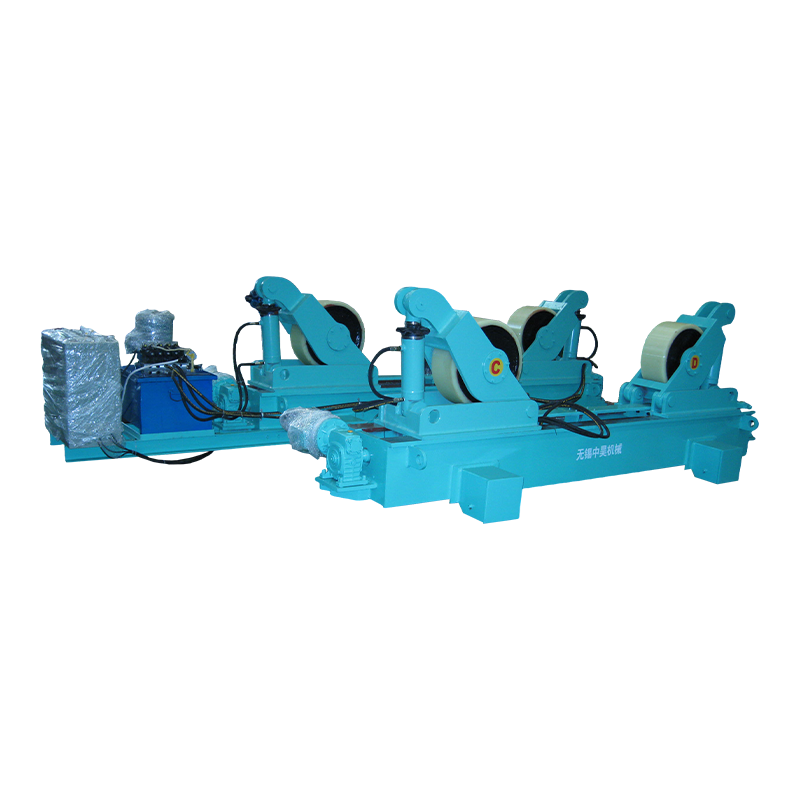

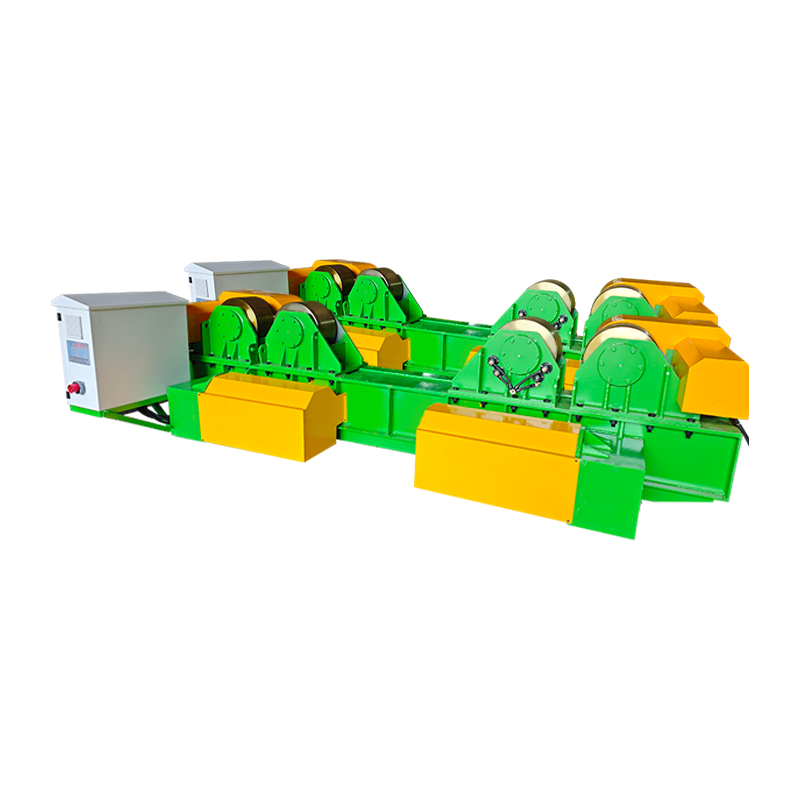

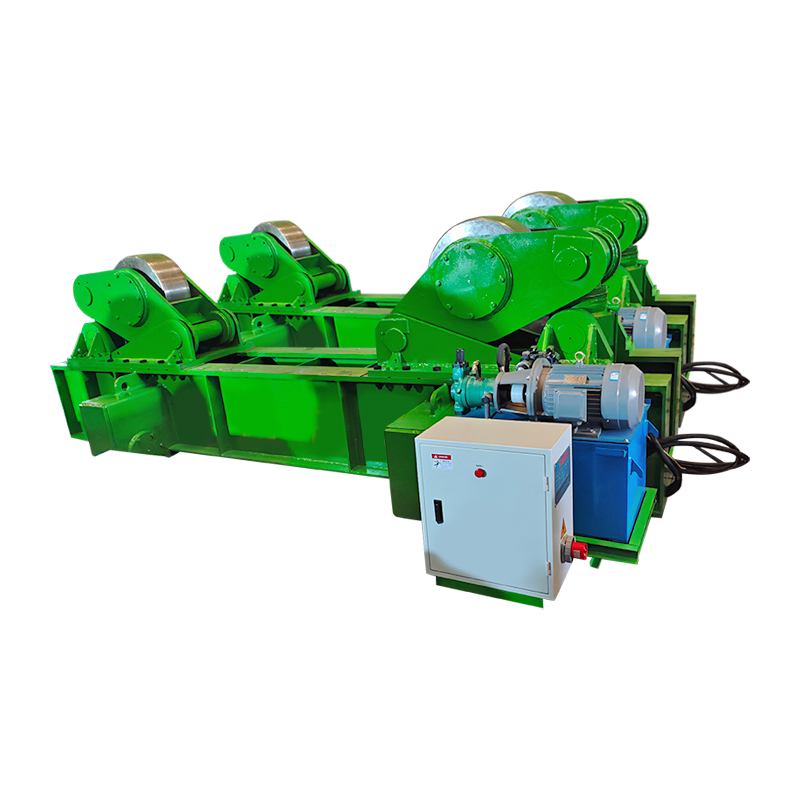

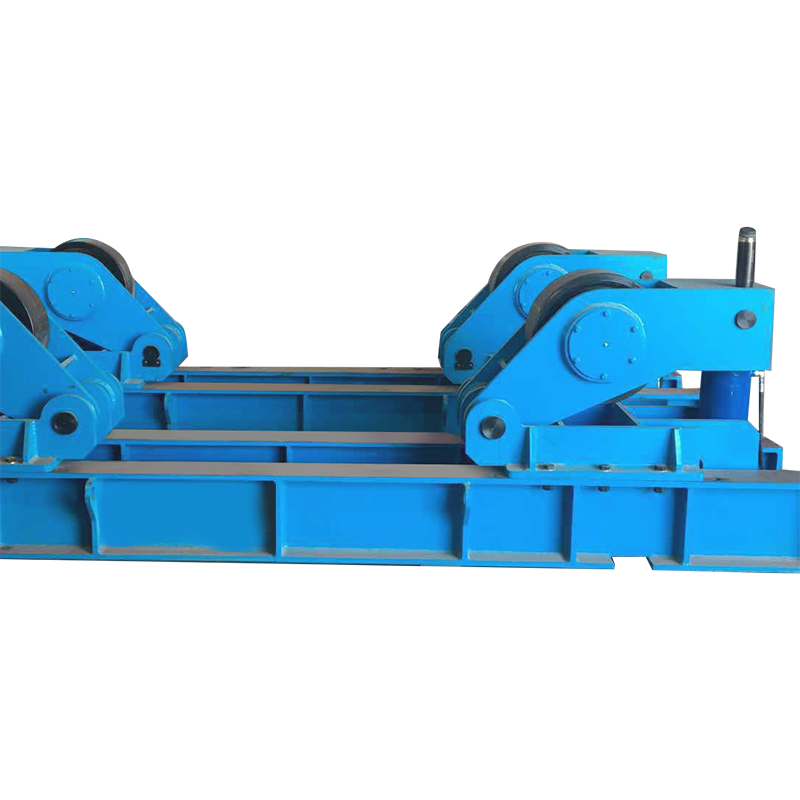

READ MOREWelding Rotator/Welding Turning Roller/Roller Frame Supplier

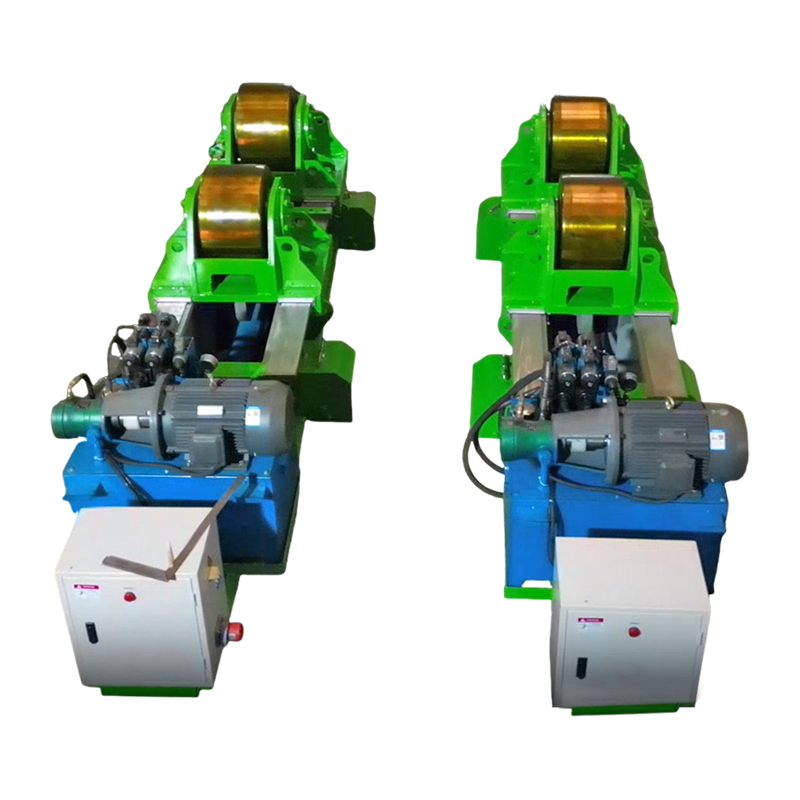

Welding rotator has a widely apply in the manufacturing of metal tank and pipe. Welding rotator is used for welding or polishing the inner&outer longitudinal seams and inner&outer circumferential seams of boilers and other pressure vessels. Welding rotator produced by WeldNice boasts advanced structure, complete functions, easy operation and provide a reliable guarantee for improving product quality.

-

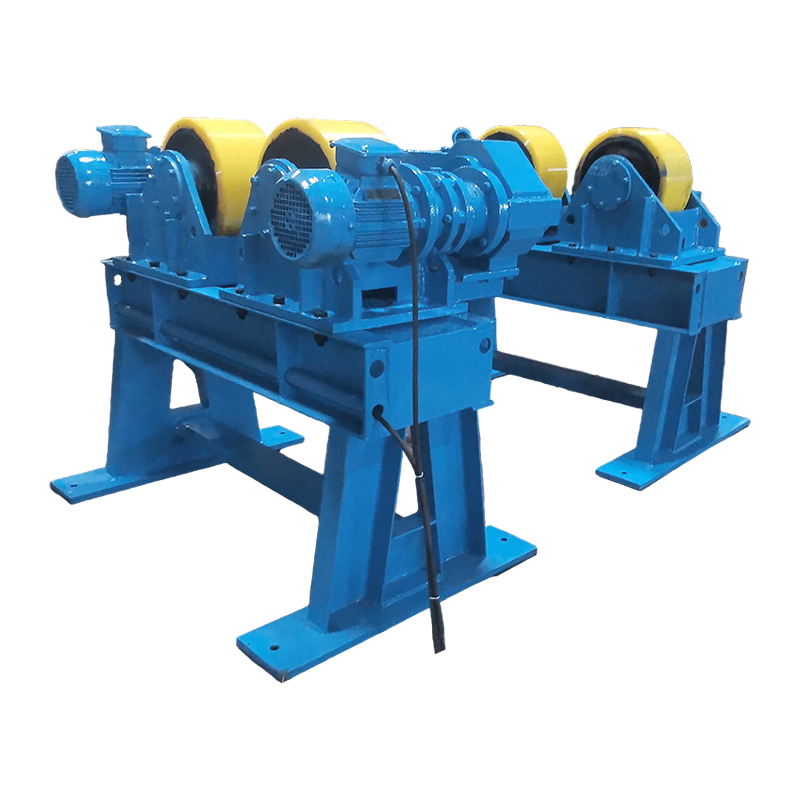

30T Welding Rotator-Heightened

This product is 30T Welding Rotator-Heightened, with a load capacity of 30 tons,...

-

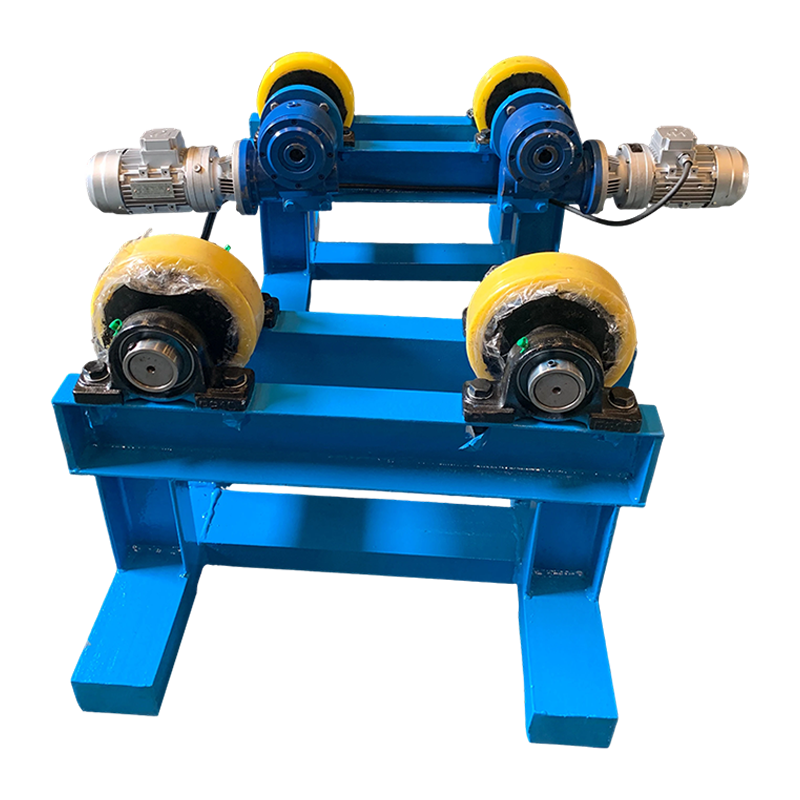

3T Welding Rotator

The 3t welding rotator is a welding auxiliary device consisting of a frame, powe...

-

500T Fit Up Welding Rotator with Manual Orbital Movement

The 500t fit up welding rotator with manual orbital movement is a heavy-duty man...

-

800T Fit Up Welding Rotator with Manual Orbital Movement

The 800T Fit Up Welding Rotator with Manual Orbital Movement is a special equipm...

-

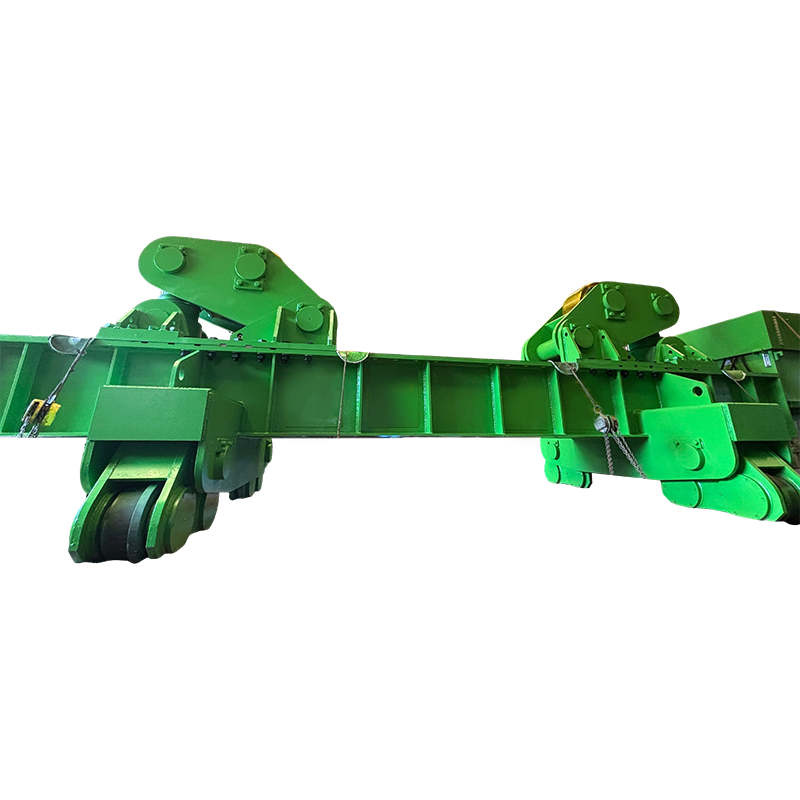

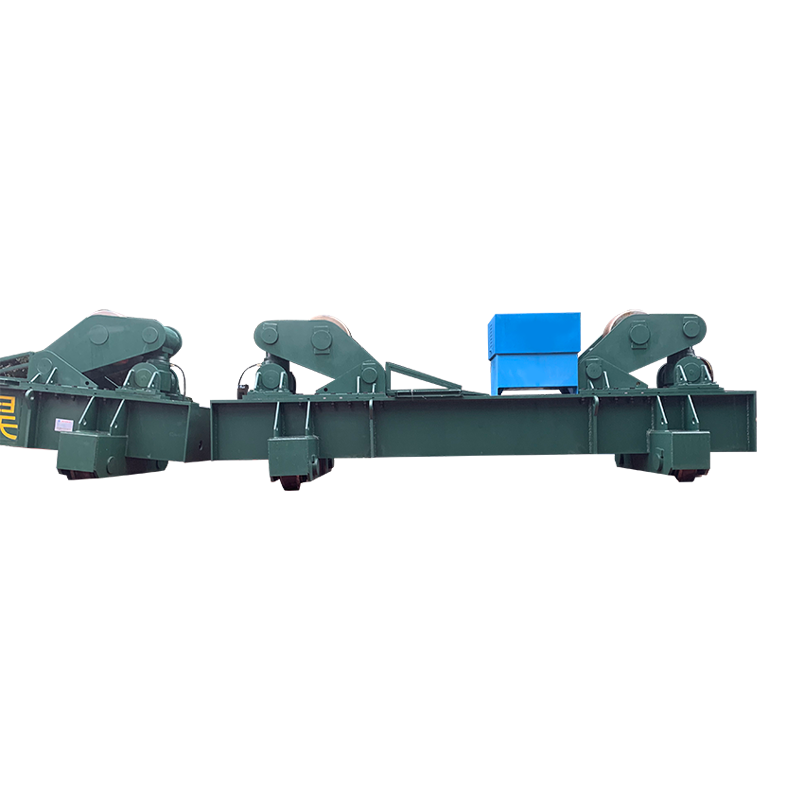

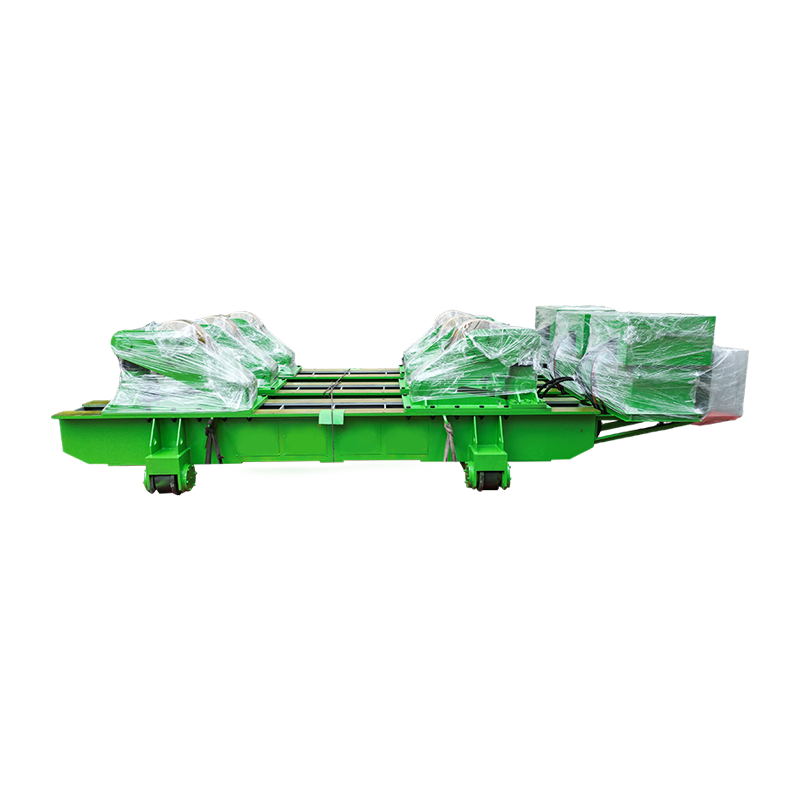

80T Fit Up Welding Rotator with Manual Orbital Movement

80t fit up welding rotator with manual orbital movement is a special equipment f...

-

40T Fit Up Welding Rotator with Hydraulic Lifting Manual Orbital Movement

The 40t fit up welding rotator with hydraulic lifting manual orbital movement is...

-

300T Fit Up Welding Rotator with Manual Orbital Movement

The 300t fit up welding rotator with manual orbital movement has a 300-ton load-...

-

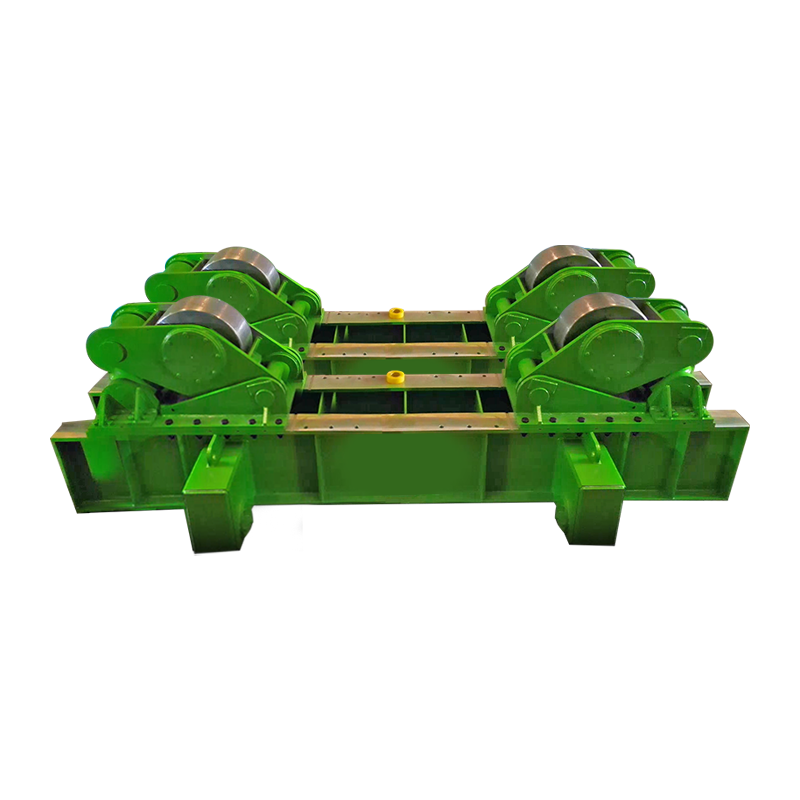

120T Fit Up Welding Rotator

The 120T Fit Up Welding Rotator has a rated load of 120 tons and is specially de...

-

1000T Fit Up Welding Rotator with Manual Orbital Movement

1000T Fit Up Welding Rotator with Manual Orbital Movement has a rated load of 1,...

-

100T Fit Up Welding Rotator with Manual Orbital Movement

100T Fit Up Welding Rotator with Manual Orbital Movement has a rated load of 100...

-

80T Fit Up Welding Rotator with Hydraulic Horizontal Pushing

80T Fit Up Welding Rotator with Hydraulic Horizontal Pushing is a special equipm...

-

-

In the realm of machinery manufacturing and pressure vessel production, the ability to maintain a consistent welding angle is often the difference between a high-strength joint and a costly defect. The 100KG Conventional Welding Positioner is engineered as a universal solution for these high-precis...

READ MORE -

In the fabrication of boilers and pressure vessels, the ability to rotate cylindrical workpieces with precision is the difference between a high-integrity weld and a structural failure. The Welding Rotator (also known as a Welding Turning Roller or Roller Frame) is an essential specialized tool for...

READ MORE

In heavy industries such as wind tower wind power generation, storage tanks, and pressure vessels, welding operations for large metal components (e.g., long-distance pipelines, giant storage tanks) have long faced three core pain points: low manual welding efficiency (single circumferential seam welding takes over 8 hours), poor consistency of weld precision (pass rate only 75%-85%), and high safety risks in high-altitude/confined space operations. To meet these industry needs, Wuxi WeldNice, with over 20 years of industry expertise, has launched welding rotators (Welding Rotator/Turning Roller/Roller Frame) featuring advanced structure and easy operation. Through automated rotation drive technology, it realizes synchronized workpiece rotation and welding, increasing the weld pass rate to over 99% while reducing labor costs by 50%, making it a core automated equipment for large-component welding.

I. Basic Cognition: Core Definition and Application Boundaries of Welding Rotators

1. Core Concept

2. Product Classification and Application Scenarios (Covered by WeldNice Core Products)

| Classification Dimension | Type | Core Parameters | Application Scenarios | WeldNice Product Advantages |

|---|---|---|---|---|

| Load Capacity | Light (≤5T) | Suitable for pipe diameters 200-1000mm | Small pressure vessels, precision pipelines | Compact structure, easy operation, ideal for mass production |

| Medium (5-50T) | Suitable for pipe diameters 800-3000mm | Conventional storage tanks, wind tower middle sections | Strong stability, adjustable roller spacing on demand | |

| Heavy-Duty (≥50T) | Suitable for pipe diameters 2000-5000mm | Large storage tanks, pressure vessels, wind tower bases | Thickened rollers and reinforced drive for stable load-bearing | |

| Structure Type | Self-Adjusting | Automatic roller spacing adaptation to workpiece diameter | Alternate production of multi-specification workpieces | No manual adjustment, improved switching efficiency |

| Adjustable | Manual/electric roller spacing adjustment | Mass production of single-specification products | Precise positioning, strong adaptability | |

| Drive Mode | Mechanical Drive | Rotational speed 0.5-10r/min | Scenarios with general requirements for speed precision | Low maintenance cost, high cost-performance |

| Frequency Conversion Drive | Rotational speed 0.1-15r/min (stepless adjustable) | High-precision welding and polishing operations | Speed fluctuation ≤±0.05r/min, uniform welds |

3. Core Functions

- Replace manual workpiece flipping/handling to reduce labor intensity and safety risks;

- Ensure stable workpiece rotation to improve weld straightness and uniformity;

- Link with welding robots to realize automated and continuous production, increasing efficiency by 3-5 times.

II. Core Technology: Key Indicators Affecting Welding Rotator Performance

1. Comparison of Core Technical Parameters (Industry Standard vs. WeldNice Standard)

| Technical Indicator | Industry General Standard | WeldNice Product Standard | Advantage Performance |

|---|---|---|---|

| Load Adaptation Range | ±10% Rated Load | ±15% Rated Load | Wider application scope for workpiece weight fluctuations |

| Speed Precision | ±0.1r/min | ±0.05r/min | Weld width error ≤0.3mm, higher precision |

| Roller Wear Resistance | ≥HRC55 | ≥HRC60 | 30% longer service life, extended maintenance cycle |

| Noise Level | ≤75dB | ≤65dB | Improved workshop working environment, compliant with environmental standards |

| Protection Level | IP54 | IP55 | Dust and water resistance, suitable for outdoor/humid operating environments |

2. Quality Assurance System

- Raw Material Inspection: Roller materials are quenched 45# steel, which can be warehoused only after passing hardness and wear resistance tests;

- Production Process Inspection: Full-time quality inspectors are assigned to key processes (e.g., welding, assembly), and laser rangefinders are used to calibrate roller spacing precision;

- Finished Product Inspection: Each equipment undergoes a 72-hour continuous operation test before leaving the factory to ensure that indicators such as load capacity and speed precision meet standards;

- After-Sales Guarantee: Provides a 12-13 month warranty period with free replacement of parts during the period, combined with 24/7 technical support.

III. Industry Trends: Automation, Customization, and Intelligence Leading Upgrades

1. Three Major Industry Development Trends and WeldNice Product Matching

| Industry Trend | Core Demand Changes | WeldNice Solutions |

|---|---|---|

| Workpiece Enlargement | Need to adapt to larger diameter and heavier workpieces (≥100T) | Customized heavy-duty welding rotator services with a maximum load capacity of 200T |

| Production Intelligence | Need to link with MES systems and welding robots | Provides intelligent models with PLC control systems, supporting remote monitoring and data tracing |

| Green Energy Conservation | Requirements for low energy consumption and low noise of equipment | Adopts high-efficiency frequency conversion motors, reducing energy consumption by 15% and noise to ≤65dB |

| Growing Customization Demand | Large differences in workpiece specifications across industries, insufficient adaptability of standardized products | Full-process ODM/OEM services, customizing equipment according to workpiece size and welding process |

English

English русский

русский Español

Español عربى

عربى