In heavy-duty industries such as energy equipment manufacturing and large-scale pressure vessel fabrication, the primary challenge is not just the weld itself, but the safe and precise manipulation of the workpiece. A 15T Conventional Welding Positioner is a heavy-duty powerhouse designed to handle...

READ MORESelf Aligning Welding Rotator Manufacturer

1 set of self aligning welding rotator is composed of 1 driving roator and 1 idler rotator, each has 4 rollers. Single motor driven or double motors driven is available.

information to be updated

-

-

In the realm of machinery manufacturing and pressure vessel production, the ability to maintain a consistent welding angle is often the difference between a high-strength joint and a costly defect. The 100KG Conventional Welding Positioner is engineered as a universal solution for these high-precis...

READ MORE -

In the fabrication of boilers and pressure vessels, the ability to rotate cylindrical workpieces with precision is the difference between a high-integrity weld and a structural failure. The Welding Rotator (also known as a Welding Turning Roller or Roller Frame) is an essential specialized tool for...

READ MORE

1. Core Product Principles

1.1 Structural Composition

1.2 Working Principle

- The driving rotator is powered by an electric motor, which drives the rollers to rotate through a reducer. The frictional force between the rollers and the workpiece is harnessed to drive the cylindrical workpiece to rotate at a constant speed.

- The idler rotator operates as a driven unit following the rotation of the workpiece. Its automatic centering structure can adaptively adjust the roller spacing according to the workpiece diameter, ensuring the coaxiality of workpiece rotation.

- The single-motor drive configuration is suitable for welding small-to-medium diameter, light-load workpieces, while the dual-motor drive configuration meets the requirements of stable rotation for large-diameter, heavy-load workpieces.

2. Typical Application Cases

| Application Industry | Workpiece Type | Selected Specification | Application Effect |

|---|---|---|---|

| Wind Power Generation | Wind Turbine Tower | Dual-motor Driven Self Aligning Welding Rotator | Enables automatic welding of circumferential seams for 10–50m long tower barrels, with coaxiality error ≤ 0.5mm, improving welding efficiency by 40% |

| Pressure Vessels | Liquefied Petroleum Gas Storage Tanks | Single-motor Driven Self Aligning Welding Rotator | Suitable for welding storage tanks with a diameter of φ1–3m, achieving uniform weld formation and a qualification rate of 99.8% |

| Petrochemical Equipment | Large-diameter Pipes | Dual-motor Driven Self Aligning Welding Rotator | Meets the welding requirements of thick-walled pipes, maintains a stable rotation speed of 0.1–10r/min, and supports multi-layer and multi-pass welding |

3. Detailed Comparison of Single-motor vs. Dual-motor Drive Models

| Comparison Dimension | Single-motor Driven Self Aligning Welding Rotator | Dual-motor Driven Self Aligning Welding Rotator |

|---|---|---|

| Power Configuration | Single motor + reducer, driving only the driving rotator | Dual motors + reducer, with synchronous drive of the driving rotator by dual motors |

| Applicable Workpieces | Diameter φ0.5–4m, weight ≤ 50 tons | Diameter φ1–10m, weight ≤ 200 tons |

| Rotation Accuracy | Coaxiality error ≤ 0.8mm | Coaxiality error ≤ 0.3mm |

| Control Method | Manual speed regulation | Variable frequency speed regulation, supporting PLC linkage control |

| Energy Consumption Level | Low, suitable for small-to-medium batch production | Moderate, suitable for mass production of heavy workpieces |

| Customization Support | Basic OEM support available | In-depth ODM support available, compatible with welding robot linkage |

Frequently Asked Questions (FAQ)

- Q: How does the automatic centering function of the Self Aligning Welding Rotator adapt to workpieces of different diameters?

A: The idler rotator of the equipment adopts a spring or lead screw adjustment structure, which can automatically expand and contract the roller spacing according to the workpiece diameter without the need for repeated manual adjustment. The applicable diameter range covers the rated specification range of the equipment, and the positioning accuracy meets industry welding standards.

- Q: In which scenarios do dual-motor drive models outperform single-motor drive models?

A: Dual-motor drive models feature stronger power output, enabling them to drive larger-diameter and heavier workpieces. Additionally, the synchronous control of dual motors can effectively prevent workpiece deviation during rotation, making them suitable for high-precision welding applications such as wind towers and large storage tanks. Single-motor drive models are more suitable for cost-effective welding operations of small-to-medium-sized workpieces.

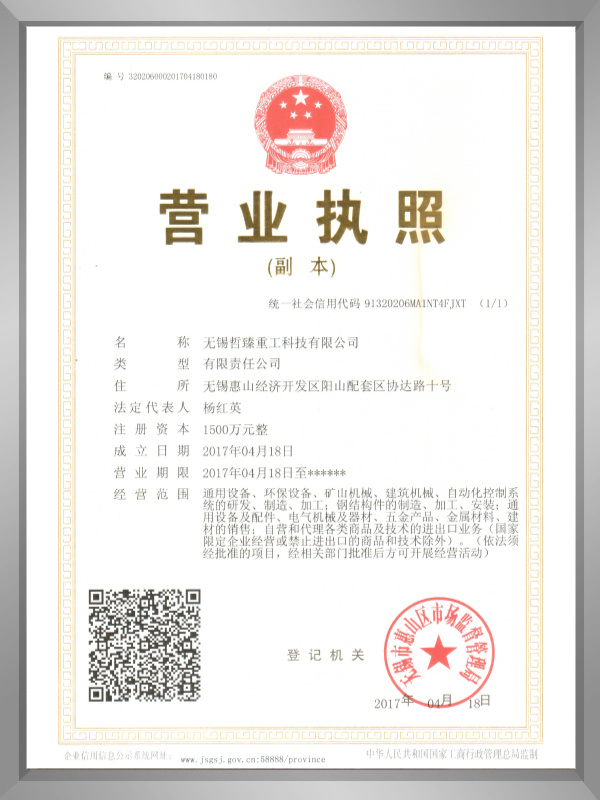

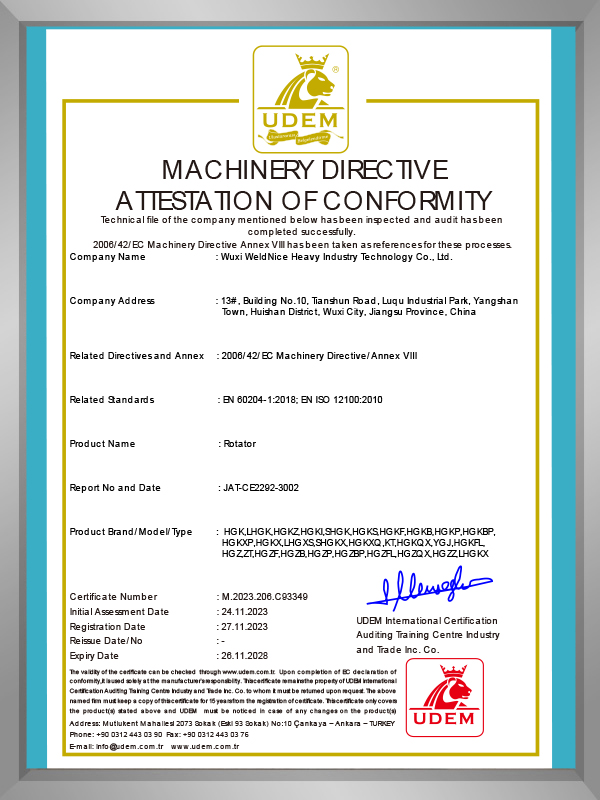

- Q: Can Wuxi WeldNice Heavy Industry Technology Co., Ltd. provide a linkage solution between the Self Aligning Welding Rotator and welding robots?

A: Yes. The company has a professional R&D team that can provide PLC linkage control transformation for the Self Aligning Welding Rotator based on the customer's existing welding robot model, realizing precise coordination between workpiece rotation and welding actions, and improving the level of automation.

- Q: How to resolve roller slipping issues in the equipment? A: First, check whether the contact area between the workpiece and the rollers is sufficient, and adjust the position of the idler rotator appropriately to increase the number of contact points. Second, inspect the wear condition of the roller surface; if wear is severe, replace the rollers in a timely manner. Finally, confirm whether the motor speed is too high, and reduce the speed to increase the frictional force between the workpiece and the rollers.

English

English русский

русский Español

Español عربى

عربى