In heavy-duty industries such as energy equipment manufacturing and large-scale pressure vessel fabrication, the primary challenge is not just the weld itself, but the safe and precise manipulation of the workpiece. A 15T Conventional Welding Positioner is a heavy-duty powerhouse designed to handle...

READ MOREWelding Manipulator/Welding Column & Boom /Welding Center/Automatic Welding Supplier

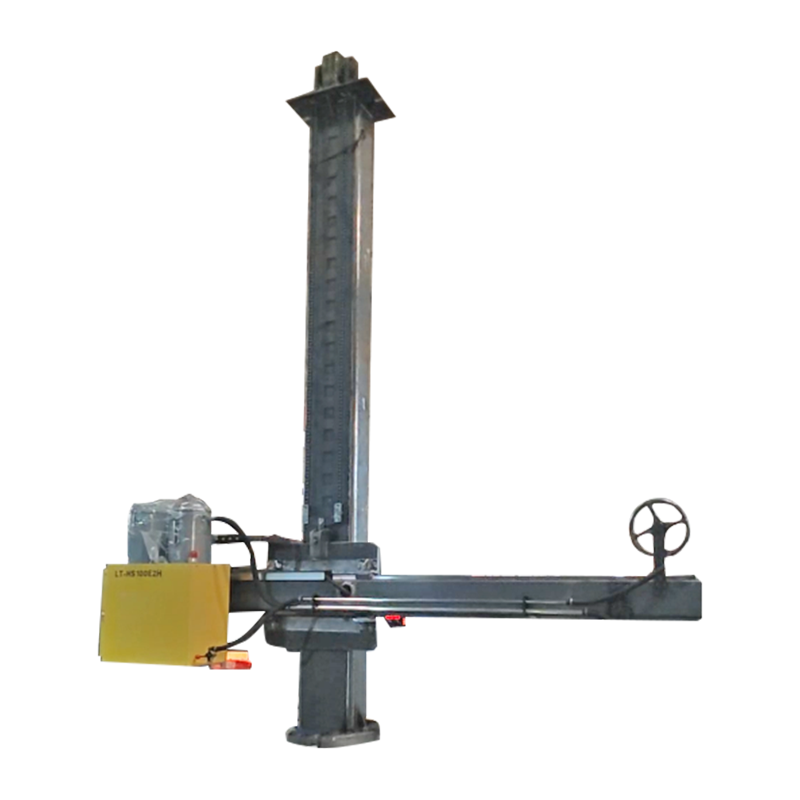

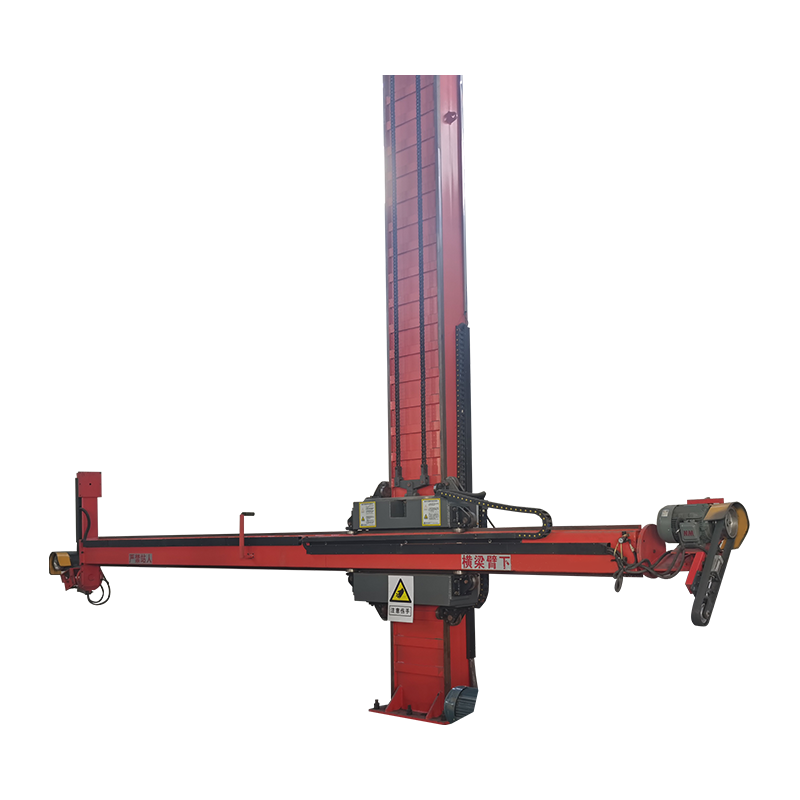

Welding column & boom has a widely apply in the manufacturing of metal tank and pipe. Welding column & boom is used for welding or polishing the inner & outer longitudinal seams and inner & outer circumferential seams of boilers and other pressure vessels. Welding column & boom produced by WeldNice boasts advanced structure, complete functions, easy operation and provide a reliable guarantee for improving product quality.WeldNice supports designing customized function according to different use of different customers. Example: Tandem Submerged Arc Welding/Narrow-gap Submerged Arc Welding/Orbital Movement/Column Rotation/Servo Motor/Seam Tracking Unit/Flux Recycle Unit/Oscillator/Strip Surfacing.

-

Polishing Column & Boom

The Polishing Column & Boom is an automated machine designed for polishing, ...

-

-

In the realm of machinery manufacturing and pressure vessel production, the ability to maintain a consistent welding angle is often the difference between a high-strength joint and a costly defect. The 100KG Conventional Welding Positioner is engineered as a universal solution for these high-precis...

READ MORE -

In the fabrication of boilers and pressure vessels, the ability to rotate cylindrical workpieces with precision is the difference between a high-integrity weld and a structural failure. The Welding Rotator (also known as a Welding Turning Roller or Roller Frame) is an essential specialized tool for...

READ MORE

Welding Manipulator form the core automatic welding equipment series of Wuxi WeldNice Heavy Industry Technology Co., Ltd. Focusing on the core needs of metal structure welding, this series of equipment has been widely used in key manufacturing fields such as storage tanks, pressure vessels, wind towers, and pipelines, providing efficient and precise welding solutions for global customers with standardized design, customized adaptability, and stable operational performance. As a professional manufacturer with over 20 years of industry experience, WeldNice's this series of products not only inherits the core advantages of "advanced structure, complete functions, and easy operation" but also becomes a reliable guarantee for improving welding quality and production efficiency through a sound quality control system and one-stop service.

English

English русский

русский Español

Español عربى

عربى