In heavy-duty industries such as energy equipment manufacturing and large-scale pressure vessel fabrication, the primary challenge is not just the weld itself, but the safe and precise manipulation of the workpiece. A 15T Conventional Welding Positioner is a heavy-duty powerhouse designed to handle...

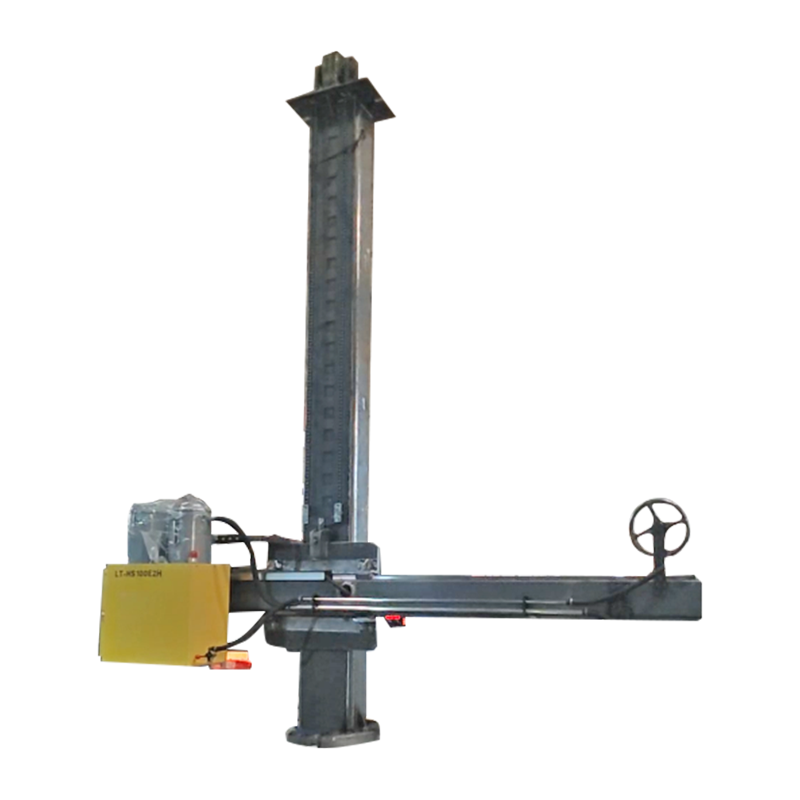

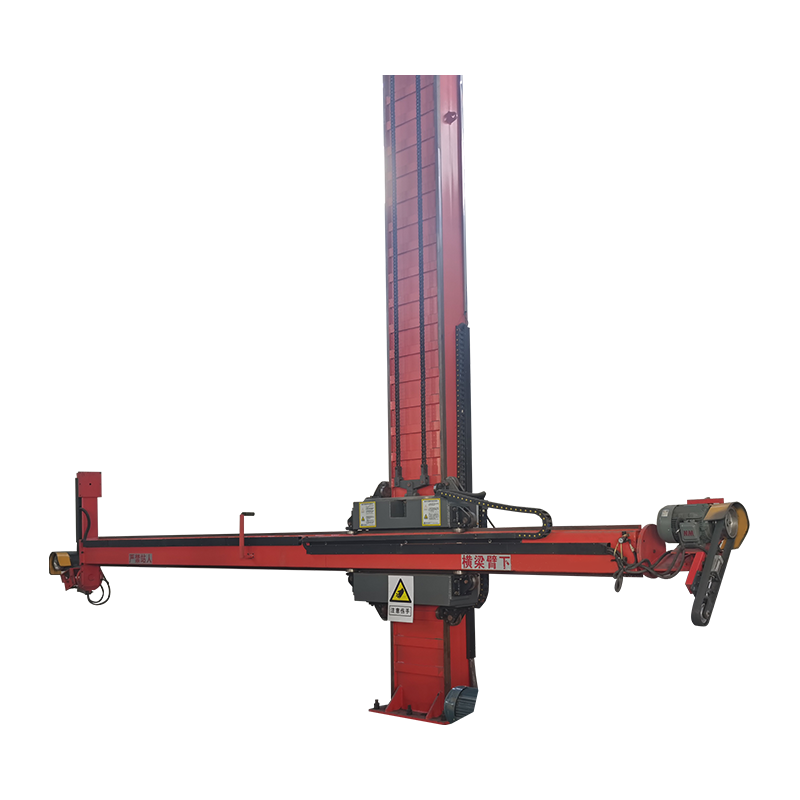

READ MORECustomized Column & Boom Manufacturer

The customized Column & Boom is an exclusive supporting equipment designed for specific welding workpiece shapes, sizes or process requirements; it can accurately adapt to the welding torch posture adjustment, welding travel path control and process parameter matching under special working conditions, solve the customized welding needs that conventional equipment cannot meet, ensure the welding precision and quality of special components, and at the same time improve the efficiency of exclusive operation scenarios and reduce manual labor intensity.

-

Polishing Column & Boom

The Polishing Column & Boom is an automated machine designed for polishing, ...

-

-

In the realm of machinery manufacturing and pressure vessel production, the ability to maintain a consistent welding angle is often the difference between a high-strength joint and a costly defect. The 100KG Conventional Welding Positioner is engineered as a universal solution for these high-precis...

READ MORE -

In the fabrication of boilers and pressure vessels, the ability to rotate cylindrical workpieces with precision is the difference between a high-integrity weld and a structural failure. The Welding Rotator (also known as a Welding Turning Roller or Roller Frame) is an essential specialized tool for...

READ MORE

Core Product Features

-

Customized Adaptability: R&D oriented to the exclusive parameters of workpieces, realizing full-dimensional matching from size specifications to process requirements, covering special welding scenarios that are difficult for conventional equipment to handle.

-

Precision Control Capability: Equipped with multi-dimensional adjustment components for welding torch posture, it can accurately locate the welding path. Welding parameters can be precisely matched with workpiece characteristics to ensure the consistency of weld quality.

-

Efficient Operation Design: The automatic adjustment mechanism reduces manual intervention, and the operation efficiency is increased by more than 30% compared with traditional manual welding. At the same time, it reduces the labor load caused by high-intensity repetitive operations.

-

Stable and Durable Structure: Adopting high-standard production and processing technology, the core components have undergone strict testing, adapting to the needs of long-term continuous operations and complex industrial environments.

Working Principle

-

Support and Positioning System: A stable frame composed of columns and beams ensures structural precision through precision machining, providing a solid benchmark for welding operations. The connection between columns and beams is fixed with high-strength bolts to ensure load-bearing stability.

-

Posture Adjustment Mechanism: Equipped with multi-degree-of-freedom adjustment components, it can accurately adjust the angle, height and position of the welding torch according to preset programs or real-time operation instructions, adapting to the operation needs of different welding surfaces.

-

Intelligent Collaborative Control: Integrating the function of storing and calling process parameters, it links welding current, voltage, travel speed and other parameters with path control to realize automatic collaboration in the welding process and reduce human errors.

Application Scenarios & Cases

Main Application Scenarios

-

Welding of special joints of large steel structures: such as special-shaped connection points of curtain wall keels, supporting components of heavy equipment and other welding operations that require precise positioning.

-

Mass production of customized workpieces: such as special mechanical parts, non-standard equipment components and other welding needs with fixed exclusive specifications.

-

High-requirement weld processing: Welding of precision components with strict standards for weld flatness and strength, complying with relevant industry welding specifications.

Typical Application Cases

-

Building Curtain Wall Steel Structure Project: Provided Customized Column & Boom for a large stone curtain wall project to solve the precise welding problem of vertical keels and adapters. It avoided vertical deviation and weld defects caused by conventional welding, ensuring compliance with the requirements of "Technical Specification for Metal and Stone Curtain Wall Engineering" JGJ133-2001. The project welding qualification rate was increased to 99.8%.

-

Anti-static Floor Bracket Production: Adapted to the welding needs of anti-static floor brackets in data centers of power grid projects. Through the customized design of beam and column structures, it realized the standardized operation of bracket welding, improved installation firmness and later expansion adaptability, and met the safety protection requirements of computer room equipment.

-

Non-standard Component Processing of Heavy Machinery: Provided exclusive Customized Column & Boom for a construction machinery manufacturer to solve the complex weld welding problem of large variable-section components. Through precise path control, welding deformation was reduced, production efficiency was increased by 40%, and the cost of subsequent correction processes was lowered.

Product Comparison Table

|

Comparison Dimension

|

Customized Column & Boom

|

Conventional Welding Equipment

|

|---|---|---|

|

Adaptability

|

Customized for exclusive workpieces, covering special sizes and processes

|

Standardized design, only applicable to general workpieces

|

|

Welding Precision

|

Weld position deviation ≤ ±0.5mm, high quality consistency

|

Dependent on manual operation, large deviation, insufficient stability

|

|

Operation Efficiency

|

Automatic adjustment, strong continuous operation capability

|

Frequent manual adjustment required, high interruption rate

|

|

Labor Intensity

|

Greatly reduces manual intervention, reduces repetitive labor

|

Relies on manual positioning and operation, high labor intensity

|

|

Application Scenarios

|

Special components, customized mass production, high-requirement welds

|

General workpieces, simple welding needs

|

Frequently Asked Questions (FAQ)

- Can this equipment be adapted to the upgrading and transformation of existing production lines? Answer: Yes. The equipment adopts a modular design and can be adaptively adjusted according to the layout and process requirements of existing production lines. Wuxi WeldNice will provide full-process technical support to ensure the seamless connection between the equipment and the existing production process.

-

Does the welding precision of the equipment meet industry standards? Answer: All core indicators of the equipment comply with relevant industry standards for welding equipment. The welding precision can reach a weld position deviation of ≤ ±0.5mm, and the weld quality meets the requirements of grade III welds and above, which is suitable for industrial scenarios with strict requirements on welding quality.

-

What should be paid attention to in the later maintenance of the equipment? Answer: The core maintenance focuses include structural connection fastening, moisture and dust prevention of the electrical system, and lubrication of moving parts. Wuxi WeldNice will provide a detailed maintenance manual and can provide regular maintenance services according to needs.

-

For operating environments with strong corrosion, are there any special protection schemes? Answer: Anti-corrosion upgrade schemes can be provided. Through processes such as galvanizing treatment and anti-corrosion coating spraying, the durability of the equipment in humid or corrosive environments is improved, and the corrosion resistance of the salt spray test can reach more than 480 hours.

Maintenance Guide

Daily Inspection (Daily/Weekly)

-

Structural Inspection: Check whether the columns and beams are bent, deformed or scratched, whether the connecting bolts are loose, and whether the anti-fall safety pins are fully inserted into the card slots.

-

Function Test: Start the equipment for no-load operation, check whether the action of the welding torch adjustment mechanism is smooth, and whether the response of the control system instructions is accurate.

-

Cleaning and Maintenance: Remove dust, welding slag and other debris on the surface of the equipment, keep the electrical control box ventilated and dry, and avoid dust accumulation.

Regular Maintenance (Monthly/Quarterly)

-

Fastening and Lubrication: Recheck all connecting bolts with a torque wrench to ensure the torque is ≥50N・m. Damaged bolts need to be replaced with high-strength bolts of the same specification above grade 8.8; apply special lubricating oil to moving parts to ensure the flexibility of the adjustment mechanism.

-

Anti-corrosion Treatment: Check the anti-corrosion coating on the surface of the equipment. For small-area rust, it needs to be polished and then touched up with anti-rust primer + metal topcoat. For large-area damage, contact the manufacturer for professional treatment; apply anti-rust grease to the anchor bolts.

-

Electrical System: Check whether the line connections are firm, whether components such as sensors and controllers are working normally, and replace aging lines or faulty components in time.

Maintenance in Special Environments

-

Humid/Corrosive Environment: Increase the cleaning frequency once a month, wipe the surface of the equipment with a dry cloth to avoid water stains; install dehumidification equipment in the warehouse to control the environmental humidity ≤60%; rinse with clean water immediately after contact with corrosive liquids, dry and touch up the anti-corrosion layer.

-

High-frequency Operation Scenarios: Conduct a comprehensive performance test every 2 months, focusing on checking the structural fatigue status and the wear of core components, and perform maintenance or replacement in time.

English

English русский

русский Español

Español عربى

عربى