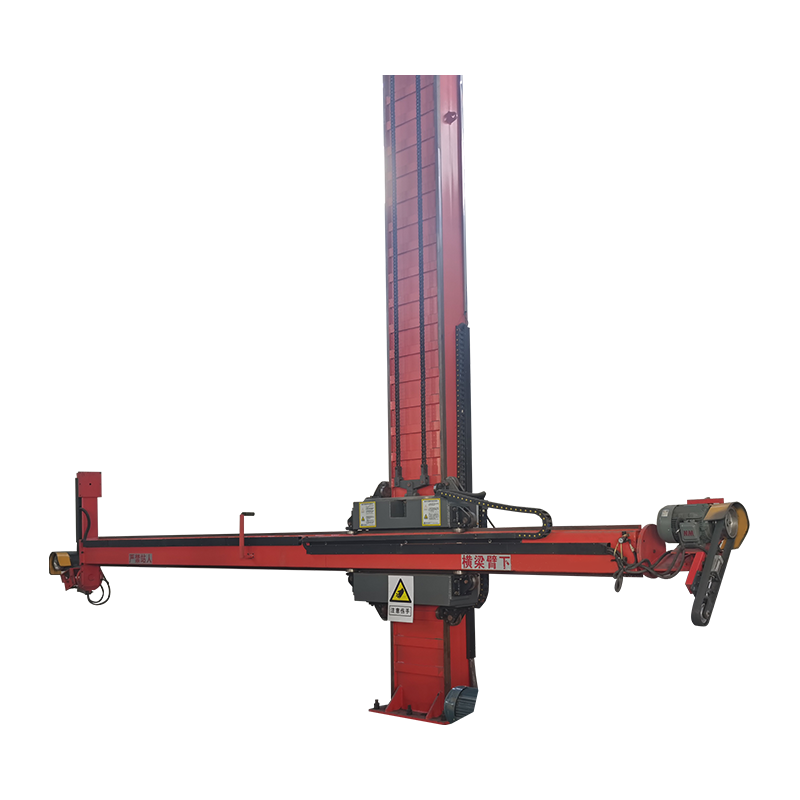

How Can Customized Column & Boom Systems Solve the Challenges of Non-Standard Welding?

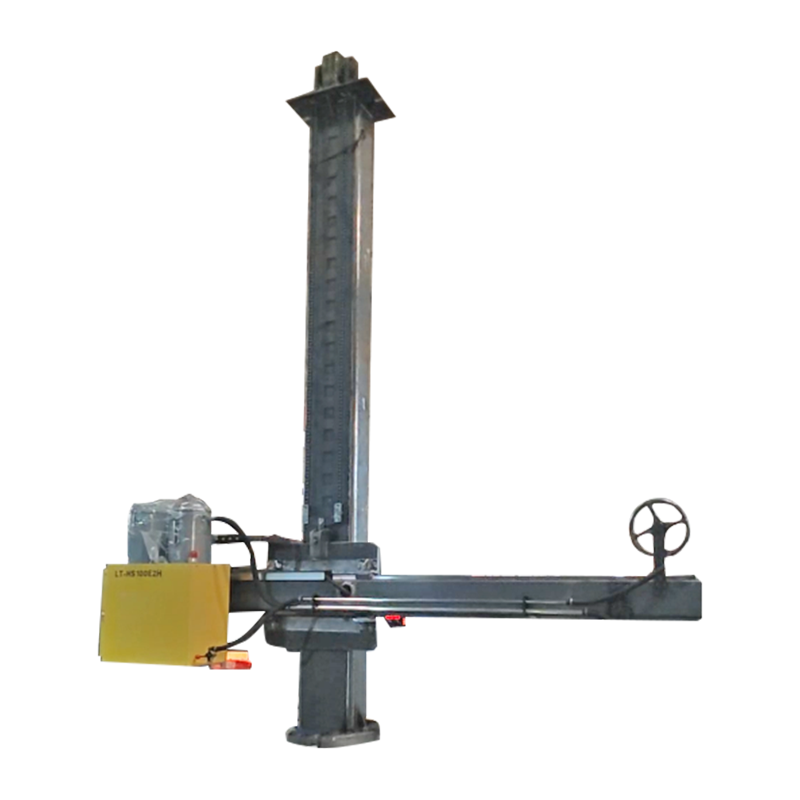

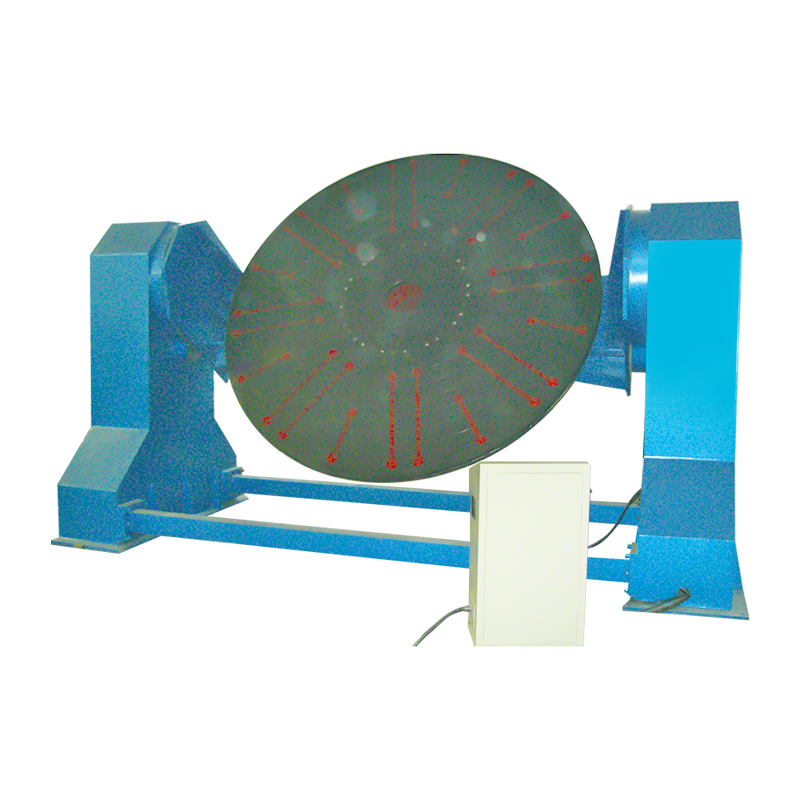

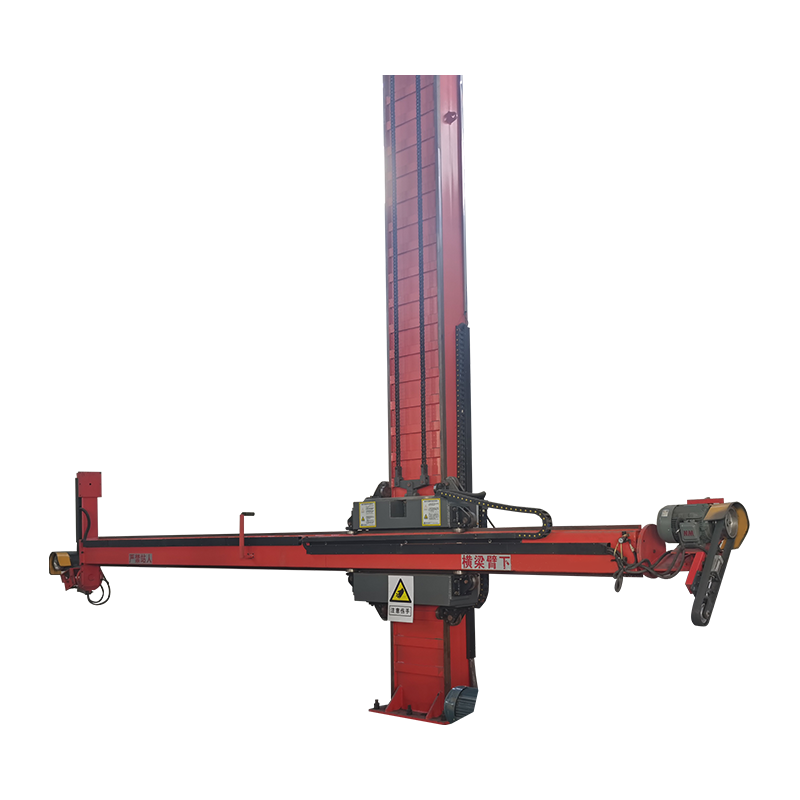

In the world of heavy-duty fabrication, conventional machinery often hits a wall when faced with irregular geometries or extreme dimensions. The Customized Column & Boom (also known as a welding manipulator) is an exclusive supporting solution engineered for workpieces that defy standard process requirements. By precisely adapting the welding torch posture and controlling the travel path under specialized conditions, this equipment bridges the gap between manual limitations and automated excellence.

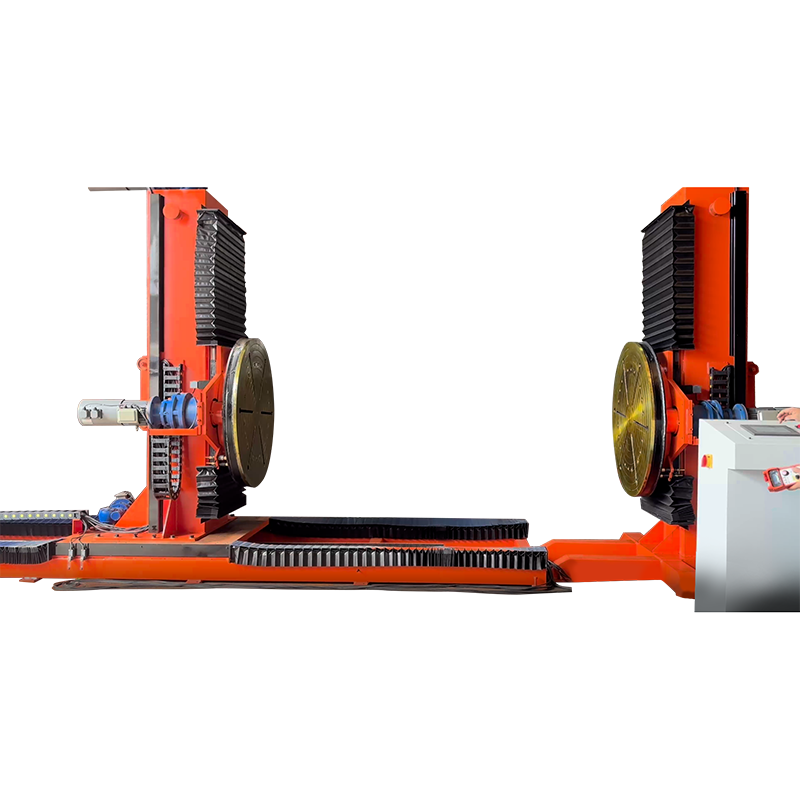

Industrial components in 2026—ranging from aerospace pressure vessels to deep-sea wind turbine foundations—demand a level of precision that "off-the-shelf" equipment cannot provide. A customized system ensures that welding travel path control and process parameter matching are perfectly synchronized with the specific metallurgy and shape of the component, significantly reducing manual labor intensity while ensuring the highest weld quality.

Technical Architecture: Precision Adaptation for Special Working Conditions

The engineering of a customized Column & Boom focuses on three pillars: structural stability, movement precision, and process integration. Whether the operation involves Submerged Arc Welding (SAW), TIG, or Plasma, the system is tailored to the specific weight and reach requirements of the exclusive operation scenario.

| Customization Pillar | Technical Specification | Industrial Benefit |

|---|---|---|

| Reach & Elevation | Extended Boom Length / Telescopic Boom | Welding Large-Diameter Vessels & Long Pipes |

| Torch Posture | Multi-Axis Motorized Slides | Accurate Access to Deep Grooves & Fillets |

| Motion Control | Servo-Driven VFD Inverters | Consistent Speed for High-Quality Penetration |

| Integration | Unified PLC with Welding Power Source | Synchronized Process Parameter Matching |

Advanced customized units often incorporate seam tracking and visual monitoring systems. These technologies allow the boom to adjust its path in real-time to compensate for workpiece deformation, ensuring that the welding torch maintains the perfect "stand-off" distance and angle regardless of the component's scale.

Strategic Advantages: Exclusive Operation Scenarios

Eliminating the Limitations of Conventional Equipment

When a project involves non-cylindrical workpieces or ultra-narrow internal welding, a standard Column & Boom is insufficient. Our customization process begins with an exclusive feasibility study of the workpiece geometry. We design specialized boom ends and mounting brackets that allow the torch to enter spaces that would be physically inaccessible to manual welders or standard robots.

- Operational Safety: Removing the welder from high-heat or confined-space environments reduces safety risks.

- Enhanced Duty Cycle: Automated travel paths allow for continuous welding without the stops associated with manual repositioning.

- Precision Repeatability: Ideal for series production of special components where every weld must meet nuclear or aerospace-grade certifications.

Reducing Manual Labor Intensity through Technology

Manual welding of large-scale components is physically exhausting and prone to human error due to fatigue. A Customized Column & Boom system automates the heavy lifting. By providing a stable, motorized platform for the welding head and flux recovery systems, the operator transitions from a manual laborer to a process technician, overseeing the operation from a safe, ergonomic console.

Conclusion: Elevating Industrial Welding Standards

The Customized Column & Boom is the foundation of high-tier industrial fabrication. By focusing on welding torch posture adjustment and precise travel control, it solves the customized needs that are the hallmarks of modern engineering.

As industrial components grow in complexity, the importance of exclusive supporting equipment will only increase. Investing in a tailored welding manipulator ensures that your facility can handle the most demanding special components with superior precision, efficiency, and safety.

Content

English

English русский

русский Español

Español عربى

عربى